Page 426 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 426

06 Chapter 16 Sheet-Metal Forming Processes and Equipment

Segmented Dies. These dies consist of individual segments that are placed inside

the part to be formed and expanded mechanically in a generally radial direction.

They are then retracted to remove the formed part. Segmented dies are relatively

inexpensive, and they can be used for large production runs.

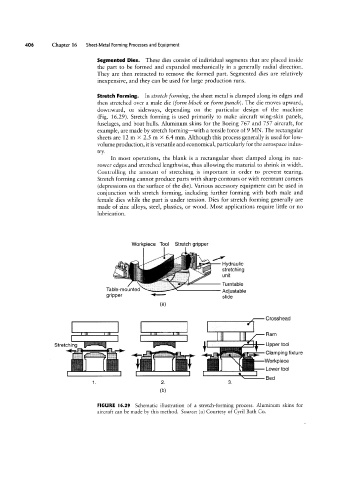

Stretch Forming. In stretch forming, the sheet metal is clamped along its edges and

then stretched over a male die (form block or form punch). The die moves upward,

downward, or sideways, depending on the particular design of the machine

(Fig. 1629). Stretch forming is used primarily to make aircraft wing-skin panels,

fuselages, and boat hulls. Aluminum skins for the Boeing 767 and 757 aircraft, for

example, are made by stretch forming-with a tensile force of 9 MN. The rectangular

sheets are 12 m >< 2.5 m >< 6.4 mm. Although this process generally is used for low-

volume production, it is versatile and economical, particularly for the aerospace indus-

try.

In most operations, the blank is a rectangular sheet clamped along its nar-

rower edges and stretched lengthwise, thus allowing the material to shrink in width.

Controlling the amount of stretching is important in order to prevent tearing.

Stretch forming cannot produce parts with sharp contours or with reentrant corners

(depressions on the surface of the die). Various accessory equipment can be used in

conjunction with stretch forming, including further forming with both male and

female dies while the part is under tension. Dies for stretch forming generally are

made of zinc alloys, steel, plastics, or wood. Most applications require little or no

lubrication.

Tool Stretch gripper

2

Hydraulic

stretching

unit

Turntable

Adjustame

stretching Table-mounted 121% Crosshead

‘*’

siide

Qfippef

(H)

\

_

'iii A ~»»»»»» < ff; or iii'1 ,_:' 5 Ram p Q fixture

UDDGHOOI

Clam in

__ \ Workpiece

Lowertool

° Bed

1. 2. 3.

(D)

FIGURE l6.29 Schematic illustration of a stretch-forming process. Aluminum skins for

aircraft can be made by this method. Source: (a) Courtesy of Cyril Bath Co.