Page 421 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 421

Section 16.6 Miscellaneous Bending and Related Operations

Q Punch Wi

= fe<e gqgen Sheet

Air bending

Bending in a four-slide machine

eeeeee eee‘ee

(bl

(a)

f

-

Adjustable

”°"

non bending Polyurethane

'Ol'

(C) (d)

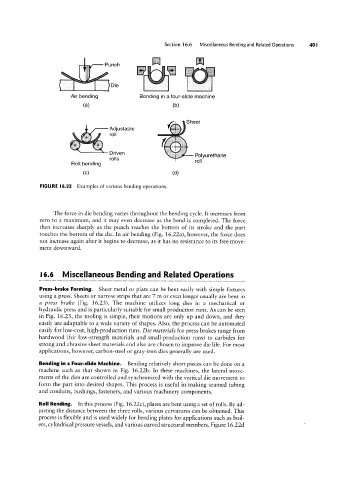

FIGURE I6.22 Examples of various bending operations.

The force in die bending varies throughout the bending cycle. It increases from

zero to a maximum, and it may even decrease as the bend is completed. The force

then increases sharply as the punch reaches the bottom of its stroke and the part

touches the bottom of the die. In air bending (Fig. 16.22a), however, the force does

not increase again after it begins to decrease, as it has no resistance to its free move-

ment downward.

l6.6 Miscellaneous Bending and Related Gperations

Press-brake Forming. Sheet metal or plate can be bent easily with simple fixtures

using a press. Sheets or narrow strips that are 7 m or even longer usually are bent in

a press brake (Fig. 1623). The machine utilizes long dies in a mechanical or

hydraulic press and is particularly suitable for small production runs. As can be seen

in Fig. 16.23, the tooling is simple, their motions are only up and down, and they

easily are adaptable to a wide variety of shapes. Also, the process can be automated

easily for low-cost, high-production runs. Die materials for press brakes range from

hardwood (for low-strength materials and small-production runs) to carbides for

strong and abrasive sheet materials and also are chosen to improve die life. For most

applications, however, carbon-steel or gray-iron dies generally are used.

Bending in a Four-slide Machine. Bending relatively short pieces can be done on a

machine such as that shown in Fig. 16.22b. In these machines, the lateral move-

ments of the dies are controlled and synchronized with the vertical die movement to

form the part into desired shapes. This process is useful in making seamed tubing

and conduits, bushings, fasteners, and various machinery components.

Roll Bending. In this process (Fig. 16.22c), plates are bent using a set of rolls. By ad-

justing the distance between the three rolls, various curvatures can be obtained. This

process is flexible and is used widely for bending plates for applications such as boil-

ers, cylindrical pressure vessels, and various curved structural members. Figure 16.22d