Page 423 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 423

Section 16.6 Miscellaneous Bending and Related Operations 03

Piercing punch

in Die biock ordie button

g

Straight flange T* ""lf; Spring-loaded stripper

% ty Sheet

JOgg|edf,anQe

Spring-loaded

Stf@1<=hf'@fiQe Pressure bushing

Fieverse flange

Shrink flange L Slug

Piercing punch (bl

3»;;;¢»,

(fi)

,HQ < feffa<=f@d>

f§i`§i`f

Sheet

Flange

Strlpper

Before

ft', ,§i¢,2Q;§Il}5' |»,, ,t,;,;,jj; plate After

Tube

Die

(C) (dl

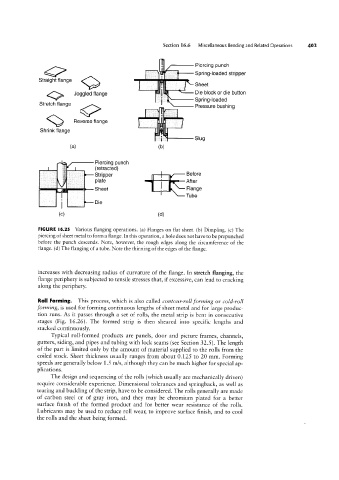

FIGURE l6.25 Various flanging operations. (a) Flanges on flat sheet. (b) Dimpling. (c) The

piercing of sheet metal to form a flange. In this operation, a hole does not have to be prepunched

before the punch descends. Note, however, the rough edges along the circumference of the

flange. (d) The flanging ofa tube. Note the thinning of the edges of the flange.

increases with decreasing radius of curvature of the flange. In stretch flanging, the

flange periphery is subjected to tensile stresses that, if excessive, can lead to cracking

along the periphery.

Roll Forming. This process, which is also called contour-roll forming or cold-roll

forming, is used for forming continuous lengths of sheet metal and for large produc-

tion runs. As it passes through a set of rolls, the metal strip is bent in consecutive

stages (Fig. 1626). The formed strip is then sheared into specific lengths and

stacked continuously.

Typical roll-formed products are panels, door and picture frames, channels,

gutters, siding, and pipes and tubing with lock seams (see Section 32.5). The length

of the part is limited only by the amount of material supplied to the rolls from the

coiled stock. Sheet thickness usually ranges from about 0.125 to 20 mm. Forming

speeds are generally below 1.5 m/s, although they can be much higher for special ap-

plications.

The design and sequencing of the rolls (Which usually are mechanically driven)

require considerable experience. Dimensional tolerances and springback, as well as

tearing and buckling of the strip, have to be considered. The rolls generally are made

of carbon steel or of gray iron, and they may be chromium plated for a better

surface finish of the formed product and for better Wear resistance of the rolls.

Lubricants may be used to reduce roll Wear, to improve surface finish, and to cool

the rolls and the sheet being formed.