Page 428 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 428

08 Chapter 16 Sheet-Metal Forming Processes and Equipment

Before o-,- Punch After

Blank Pressure B|ankhO|de|- li DO

Stripper rms

l

'

1

_

Punch

Blank holder

Die

D

I

n

I

p

force

...hg.b

Ode'

,r,rV

.\R. T

;

i g S an Blank ,@&&, .,Vr_rrrr rrrrrr,r,r C i T

_f <1

Die

(draw ring)

., _.,,» f

Blank Drawn Cup

(3) (D)

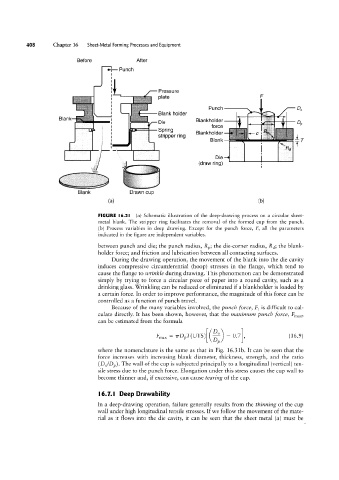

FIGURE l6.3| (a) Schematic illustration of the deep-drawing process on a circular sheet-

metal blank. The stripper ring facilitates the removal of the formed cup from the punch.

(b) Process variables in deep drawing. Except for the punch force, F, all the parameters

indicated in the figure are independent variables.

between punch and die; the punch radius, Rp; the die-corner radius, Rd; the blank-

holder force; and friction and lubrication between all contacting surfaces.

During the drawing operation, the movement of the blank into the die cavity

induces compressive circumferential (hoop) stresses in the flange, which tend to

cause the flange to wrinkle during drawing. This phenomenon can be demonstrated

simply by trying to force a circular piece of paper into a round cavity, such as a

drinking glass. Wrinkling can be reduced or eliminated if a blankholder is loaded by

a certain force. In order to improve performance, the magnitude of this force can be

controlled as a function of punch travel.

Because of the many variables involved, the punch force, F, is difficult to cal-

culate directly. It has been shown, however, that the maximum punch force, Fmax,

can be estimated from the formula

= ¢fD,,T(UTs)l(%> - oil, (16.9)

P

where the nomenclature is the same as that in Fig. 16.31b. It can be seen that the

force increases with increasing blank diameter, thickness, strength, and the ratio

(DO/Dp). The wall of the cup is subjected principally to a longitudinal (vertical) ten-

sile stress due to the punch force. Elongation under this stress causes the cup wall to

become thinner and, if excessive, can cause tearing of the cup.

l6.7.l Deep Drawability

In a deep-drawing operation, failure generally results from the thinning of the cup

wall under high longitudinal tensile stresses. If we follow the movement of the mate-

rial as it flows into the die cavity, it can be seen that the sheet metal (a) must be