Page 433 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 433

Section 16.8 Rubber Forming and Hydroforming 4|3

Scored Integral Pop-top

region rivet cantilever

I I I

(H) (b)

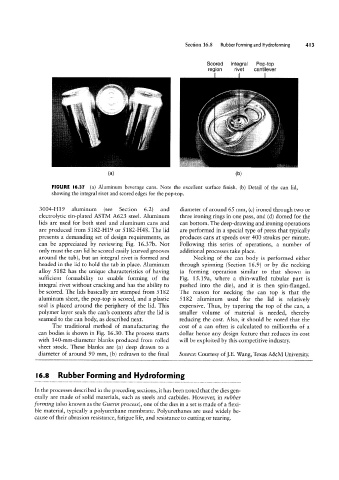

FIGURE l6.37 (a) Aluminum beverage cans. Note the excellent surface finish. (b) Detail of the can lid,

showing the integral rivet and scored edges for the pop-top.

3004-H19 aluminum (see Section 6.2) and diameter of around 65 mm, (c) ironed through two or

electrolytic tin-plated ASTM A623 steel. Aluminum three ironing rings in one pass, and (d) domed for the

lids are used for both steel and aluminum cans and can bottom. The deep-drawing and ironing operations

are produced from 5182-H19 or 5182-H48. The lid are performed in a special type of press that typically

presents a demanding set of design requirements, as produces cans at speeds over 400 strokes per minute.

can be appreciated by reviewing Fig. 16.37b. Not Following this series of operations, a number of

only must the can lid be scored easily (curved grooves additional processes take place.

around the tab), but an integral rivet is formed and Necking of the can body is performed either

headed in the lid to hold the tab in place. Aluminum through spinning (Section 16.9) or by die necking

alloy 5182 has the unique characteristics of having (a forming operation similar to that shown in

sufficient formability to enable forming of the Fig. 15.19a, where a thin-walled tubular part is

integral rivet without cracking and has the ability to pushed into the die), and it is then spin-flanged.

be scored. The lids basically are stamped from 5182 The reason for necking the can top is that the

aluminum sheet, the pop-top is scored, and a plastic 5182 aluminum used for the lid is relatively

seal is placed around the periphery of the lid. This expensive. Thus, by tapering the top of the can, a

polymer layer seals the can’s contents after the lid is smaller volume of material is needed, thereby

seamed to the can body, as described next. reducing the cost. Also, it should be noted that the

The traditional method of manufacturing the cost of a can often is calculated to millionths of a

can bodies is shown in Fig. 16.30. The process starts dollar hence any design feature that reduces its cost

with 140-mm-diameter blanks produced from rolled will be exploited by this competitive industry.

sheet stock. These blanks are (a) deep drawn to a

diameter of around 90 mm, (b) redrawn to the final Source: Courtesy of ].E. Wang, Texas ASCM University.

l6.8 Rubber Forming and Hydroforming

In the processes described in the preceding sections, it has been noted that the dies gen-

erally are made of solid materials, such as steels and carbides. However, in rubber

forming (also known as the Guerin process), one of the dies in a set is made of a flexi-

ble material, typically a polyurethane membrane. Polyurethanes are used widely be-

cause of their abrasion resistance, fatigue life, and resistance to cutting or tearing.