Page 435 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 435

die

‘fjf

if Centering Section 16.8 Rubber Forming and Hydroforming 4l5

eee,,e eeeeeeeeeeeeeee

PWC” ~~== e e it

Bottom Die-holder

Slide plate

plate

~ 1

5 if

ee'e

H0r;Z0ma|

TOD die

yy

`i _.`,

holder

I.. t , 5.,. 5, ig. Cylinder

bfackel

.. ' " if . ll'l` i. .pp L, Die_ho|der

Bed plate Hydroformed part

(al (bl

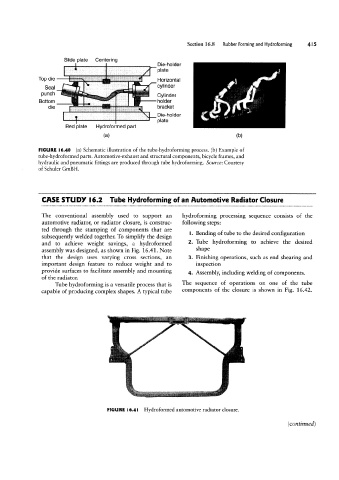

FIGURE l6.40 (a) Schematic illustration of the tube-hydroforming process. (b) Example of

tube-hydroformed parts. Automotive-exhaust and structural components, bicycle frames, and

hydraulic and pneumatic fittings are produced through tube hydroforming. Source: Courtesy

of Schuler GmBH.

CASE STUDY l6.2 Tube Hydroforming of an Automotive Radiator Closure

The conventional assembly used to support an hydroforming processing sequence consists of the

automotive radiator, or radiator closure, is construc- following steps:

ted through the stamping of components that are

I. Bending of tube to the desired configuration

subsequently Welded together. To simplify the design

and to achieve weight savings, a hydroformed 2. Tube hydroforming to achieve the desired

assembly was designed, as shown in Fig. 16.41. Note Shape

that the design uses varying cross sections, an 3. Finishing operations, such as end shearing and

important design feature to reduce weight and to inspection

provide surfaces to facilitate assembly and mounting 4_ Assembly, including Welding of Componenw

of the radiator. _

Tube hydroforming is a versatile process that is The Sequence of Opefatlons OH 0116 Of the tube

capable of producing complex shapes. A typical tube components of the closure is shown in Fig. 16.42.

,... ...in

~ '

FIGURE l6.4l Hydroformed automotive radiator closure.

(continued )