Page 425 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 425

Section 16.6 Miscellaneous Bending and Related Operations 0

Dimpling, Piercing, and Flaring. In dimpling (Fig. 16.25b), a hole first is punched

and then expanded into a flange. Flanges also may be produced by piercing with a

shaped punch (Fig. 16.25c). Tube ends can be flanged by a similar process

(Fig. 16.25d). When the bend angle is less than 90° (as in fittings with conical ends),

the process is called flaring. The condition of the edges (see Fig. 16.3) is important in

these operations. Stretching the material causes high tensile stresses along the periph-

ery (tensile hoop stresses), which can lead to cracking and tearing of the flange.

As the ratio of flange diameter to hole diameter increases, the strains increase

proportionately. Depending on the roughness of the edge, there will be a tendency for

cracking along the outer periphery of the flange. To reduce this possibility, sheared or

punched edges may be shaved off with a sharp tool (see Fig. 16.9) to improve the

surface finish of the edge.

Hemming and Seaming. In the hemming process (also called flattening), the edge

of the sheet is folded over itself (Fig. 16.23c). Hemming increases the stiffness of the

part, improves its appearance, and eliminates sharp edges. Seaming involves joining

two edges of sheet metal by hemming (Fig. 16.23d). Double seams are made by a

similar process using specially shaped rollers for watertight and airtight joints, such

as are needed in food and beverage containers.

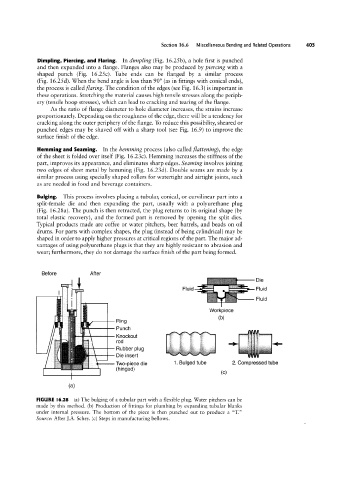

Bulging. This process involves placing a tubular, conical, or curvilinear part into a

split-female die and then expanding the part, usually with a polyurethane plug

(Fig. 16.28a). The punch is then retracted, the plug returns to its original shape (by

total elastic recovery), and the formed part is removed by opening the split dies.

Typical products made are coffee or water pitchers, beer barrels, and beads on oil

drums. For parts with complex shapes, the plug (instead of being cylindrical) may be

Fluid

shaped in order to apply higher pressures at critical regions of the part. The major ad-

vantages of using polyurethane plugs is that they are highly resistant to abrasion and

wear; furthermore, they do not damage the surface finish of the part being formed.

Before After tt't~ Die

Fluid

workpiece

i' §

Ring lb)

Punch c”si

L

Knockout

Die insert

ccss

-|'W0-pieCe die 1. Bulged tube 2. Compressed tube

(hinged) (C)

(H)

FIGURE |6.28 (a) The bulging of a tubular part with a flexible plug. Water pitchers can be

made by this method. (b) Production of fittings for plumbing by expanding tubular blanks

under internal pressure. The bottom of the piece is then punched out to produce a “T.”

Source: After ].A. Schey. (c) Steps in manufacturing bellows.