Page 585 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 585

Chapter 21 Fundamentals of Machining

Chip breaker

Chip

Without chip breaker §

With chip breaker Flake face Clamp

of tool

Chip breaker

Tool

(21) (D)

Rake face

Radius Positive rake 0° rake

(C)

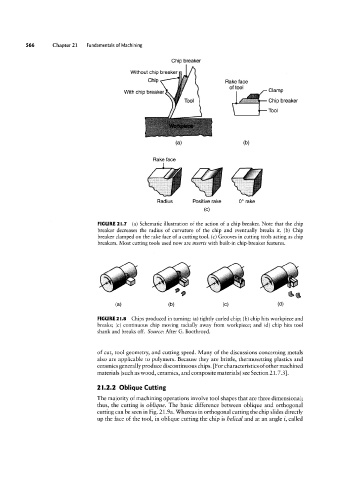

FIGURE 2l.'I (a) Schematic illustration of the action of a chip breaker. Note that the chip

breaker decreases the radius of curvature of the chip and eventually breaks it. (b) Chip

breaker clamped on the rake face of a cutting tool. (c) Grooves in cutting tools acting as chip

breakers. Most cutting tools used now are inserts with built-in chip-breaker features.

e g g §

(a) (D) (C) (Ol)

FIGURE 2l.8 Chips produced in turning: (a) tightly curled chip; (b) chip hits workpiece and

breaks; (c) continuous chip moving radially away from workpiece; and (d) chip hits tool

shank and breaks off. Source: After G. Boothroyd.

of cut, tool geometry, and cutting speed. Many of the discussions concerning metals

also are applicable to polymers. Because they are brittle, thermosetting plastics and

ceramics generally produce discontinuous chips. [For characteristics of other machined

materials (such as wood, ceramics, and composite materials) see Section 21.7.3].

2l.2.2 Oblique Cutting

The majority of machining operations involve tool shapes that are three dimensional;

thus, the cutting is oblique. The basic difference between oblique and orthogonal

cutting can be seen in Fig. 21.9a. Whereas in orthogonal cutting the chip slides directly

up the face of the tool, in oblique cutting the chip is helical and at an angle i, called