Page 588 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 588

.

eeee

i i oioo - Tool

Section 21.3

Cutting Forces and Power

1%

(IZ

Q

CNP

oooo F

Tri 'iii

~

oo

- ~""'

ooooo f~'f r ve

-T' ~~~~ ’”‘

4, V

oooo

- -

,,,,

(H) W K,,f,Y, ZVE

(D)

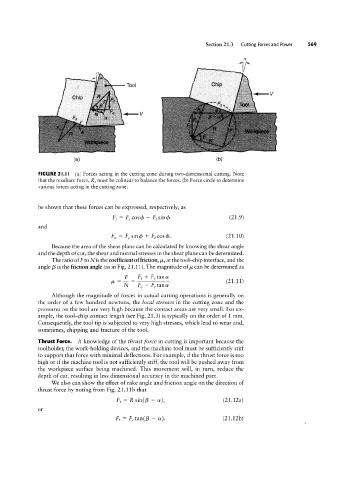

FIGURE 2l.ll (a) Forces acting in the cutting zone during two-dimensional cutting. Note

that the resultant force, R, must be colinear to balance the forces. (b) Force circle to determine

various forces acting in the cutting zone.

be shown that these forces can be expressed, respectively, as

FS = Fccosda - Fzsinda (21.9)

and

Fn = FC sinq5 + F,c0s<;'>. (21.10)

Because the area of the shear plane can be calculated by knowing the shear angle

and the depth of cut, the shear and normal stresses in the shear plane can be determined.

The ratio of F to N is the coefficient of friction, /st, at the tool-chip interface, and the

angle B is the friction angle (as in Fig. 21.1 1). The magnitude of /.L can be determined as

_ 5 _ F, + Fctana

21.11

.

M N Fc - Fttana ( )

Although the magnitude of forces in actual cutting operations is generally on

the order of a few hundred newtons, the local stresses in the cutting zone and the

pressures on the tool are very high because the Contact areas are very small. For ex-

ample, the tool-chip contact length (see Fig. 21.3) is typically on the order of 1 mm.

Consequently, the tool tip is subjected to very high stresses, which lead to wear and,

sometimes, chipping and fracture of the tool.

Thrust Force. A knowledge of the thrust force in cutting is important because the

toolholder, the work-holding devices, and the machine tool must be sufficiently stiff

to support that force with minimal deflections. For example, if the thrust force is too

high or if the machine tool is not sufficiently stiff, the tool will be pushed away from

the workpiece surface being machined. This movement will, in turn, reduce the

depth of cut, resulting in less dimensional accuracy in the machined part.

We also can show the effect of rake angle and friction angle on the direction of

thrust force by noting from Fig. 21.11b that

F, = R sin(B - cr), (21.12a)

or

Ft = FCtan(B - cr). (21.12b)