Page 583 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 583

Chapter 21 Fundamentals of Machining

inf »{ ,Z ' .1 gr”

" is

1 5 f 4 Y »<‘

»fg,; §?{i".;}iZ1,*,? " ._;

'»= Q.. iifinf if? ”3§¢.",f 5.2 iw

._

2.1 .gi V . '

sf

ff?

g

\

4'

»

"uf xyéirs

:»

» ei

“

f ww? V

V'

-' ,,

*rg*

. '_»if'r~

¢» .f 53% fsck;

if

'°

Ili" “xg

', ~

'xx

».',.,,§'~.'<g §‘

g

J!

w

11

. wif ~»f .~i, ii ;

1*

Built-up us€}%,! (Ji wig' il ~ tA§'\ i

was

1 21

»

7,

edge Hardness (HK) s ' i T" »@ v vig; 2 E~ "

>

.

s > .elf

W . C

,.~.a-,‘**°l§=- *_ J _ I

(H) (C)

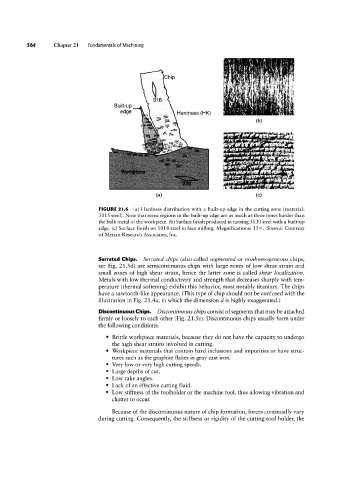

FIGURE 2l.6 (a) Hardness distribution with a built-up edge in the cutting zone (material:

31 15 steel). Note that some regions in the built-up edge are as much as three times harder than

the bulk metal of the workpiece. (b) Surface finish produced in turning 5130 steel with a built-up

edge. (c) Surface finish on 1018 steel in face milling. Magnifications: 15 ><. Source: Courtesy

of Metcut Research Associates, Inc.

Serrated Chips. Serrated chips (also called segmented or nonhomogeneous chips,

see Fig. 21.5d) are semicontinuous chips with large zones of low shear strain and

small zones of high shear strain, hence the latter zone is called shear localization.

Metals with low thermal conductivity and strength that decreases sharply with tem-

perature (thermal softening) exhibit this behavior, most notably titanium. The chips

have a sawtooth-like appearance. (This type of chip should not be confused with the

illustration in Fig. 21.4a, in which the dimension d is highly exaggerated.)

Discontinuous Chips. Discontinuous chips consist of segments that may be attached

firmly or loosely to each other (Fig. 21.5e). Discontinuous chips usually form under

the following conditions:

° Brittle workpiece materials, because they do not have the capacity to undergo

the high shear strains involved in cutting.

° Workpiece materials that contain hard inclusions and impurities or have struc-

tures such as the graphite flakes in gray cast iron.

° Very low or very high cutting speeds.

° Large depths of cut.

° Low rake angles.

° Lack of an effective cutting fluid.

° Low stiffness of the toolholder or the machine tool, thus allowing vibration and

chatter to occur.

Because of the discontinuous nature of chip formation, forces continually vary

during cutting. Consequently, the stiffness or rigidity of the cutting-tool holder, the