Page 592 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 592

Section 21.4 Temperatures in Cutting 573

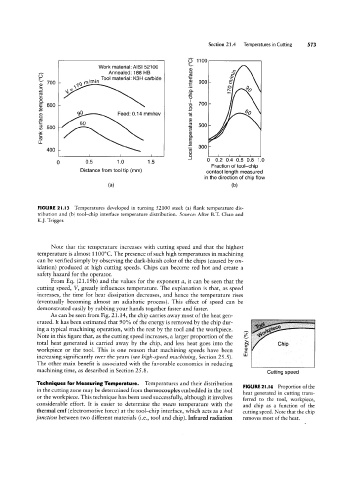

Note that the temperature increases with cutting speed and that the highest

temperature is almost 1 100°C. The presence of such high temperatures in machining

can be verified simply by observing the dark-bluish color of the chips (caused by ox-

idation) produced at high cutting speeds. Chips can become red hot and create a

safety hazard for the operator.

From Eq. (21.19b) and the values for the exponent a, it can be seen that the

cutting speed, V, greatly influences temperature. The explanation is that, as speed

increases, the time for heat dissipation decreases, and hence the temperature rises

(eventually becoming almost an adiabatic process). This effect of speed can be

demonstrated easily by rubbing your hands together faster and faster.

As can be seen from Fig. 21.14, the chip carries away most of the heat gen-

erated. It has been estimated that 90% of the energy is removed by the chip dur- gin ; ~ ~ ' ic lé ii .V

ing a typical machining operation, with the rest by the tool and the workpiece. Ge

Note in this figure that, as the cutting speed increases, a larger proportion of the en ~==1°"`°

total heat generated is carried away by the chip, and less heat goes into the 5 Chip

workpiece or the tool. This is one reason that machining speeds have been GJ

C

increasing significantly over the years (see big/2-speed machining, Section 25.5). LU

The other main benefit is associated with the favorable economics in reducing

machining time, as described in Section 25.8. Cutting speed

Techniques for Measuring Temperature. Temperatures and their distribution FIGURE 2l.|4 Proportion of the

in the cutting zone may be determined from thermocouples embedded in the tool

heat generated in cutting trans-

or the workpiece. This technique has been used successfully, although it involves

ferred to the tool, workpiece,

considerable effort. It is easier to determine the mean temperature with the and chip as a function of the

thermal emf (electromotive force) at the tool-chip interface, which acts as a hot cutting speed. Note that the chip

junction between two different materials (i.e., tool and chip). Infrared radiation removes most of the heat.

Flanktemperature(°C)

73.3

surface

-|> \| CD U1

*-l:.'. O O O O

2.9¢

O O O O

gs

O||||

emf

l'*,’3.

4.

iw

Q

5' 2

.A

ff#

65

85QE30

I?21sv 5;

ef§ 3°‘ij

*UE e =' ._ _| S

55,2 3O 2

go. *1 1,7 3

9>f

E92

V5*

333 QQ.

o

-*'r|

&’.cr>&’.

HQ I6Q‘-E32

“nn 5'e

Bo.

E851

E* SD

397:5933

§L*

§ooQ

EE'

Im I3 #_ 3

RE.

3005

U1 > Qo

Ewa

CDQ.O

fm/.

ge

"1

<<1>

CD

go

Pa

f/1%

C

O L

§e caltemperatureattool-chipinterface(°C)

Wm

_L

8 S 8 8 8

>§OJU1\|CO-*

-”T"?v‘

ga 2.8OII|

“E

331'

mm?

H2

Q=,Q,9,|\>

me -.

D-f-r

CD-O

9.‘°=@17

NE

OFD

~_/:5""" me.

»-°-O

:\»-~

9..§§b>

.Q.‘f

9==>J>9Si’QQ’

i`2;€<=°

§<_5°r*

sf*O