Page 593 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 593

Chapter 21 Fundamentals of Machining

from the cutting zone may be monitored with a radiation pyroineter. However, this

technique indicates only surface temperatures; the accuracy of the results depends on

the emissivity of the surfaces, which is difficult to determine accurately.

2l.5 Tool Life: Wear and Failure

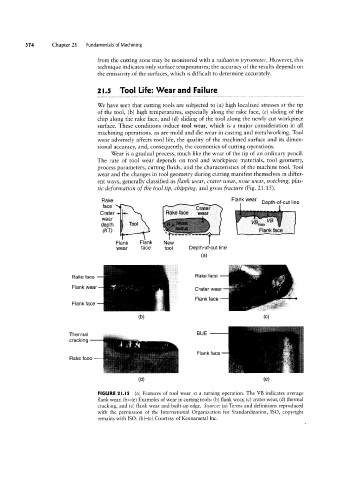

We have seen that cutting tools are subjected to (a) high localized stresses at the tip

of the tool, (b) high temperatures, especially along the rake face, (c) sliding of the

chip along the rake face, and (d) sliding of the tool along the newly cut workpiece

surface. These conditions induce tool wear, which is a major consideration in all

machining operations, as are mold and die wear in casting and metalworking. Tool

wear adversely affects tool life, the quality of the machined surface and its dimen-

sional accuracy, and, consequently, the economics of cutting operations.

Wear is a gradual process, much like the wear of the tip of an ordinary pencil.

The rate of tool wear depends on tool and workpiece materials, tool geometry,

process parameters, cutting fluids, and the characteristics of the machine tool. Tool

wear and the changes in tool geometry during cutting manifest themselves in differ-

ent ways, generally classified as flank wear, crater wear, nose wear, notching, plas-

tic deformation of the tool tip, chipping, and gross fracture (Fig. 2l.15).

Rake Hankwear Depth-of-cut line

face

Crater V

Weal'

depth VBM B

(KT) Flank face

Flank Flank New

wear face tool Depth-of-cut line

Flake face Rake face

Flank wear Crater wear

Flank face

Flank face

(D) (C)

BUE *T

Thermal

cracking_

Flank face-

Flake face

(Cl) (9)

FIGURE 2l.l5 (a) Features of tool wear in a turning operation. The VB indicates average

flank wear. (bl-(e) Examples of wear in cutting tools: (b) flank wear, (c) crater wear, (d) thermal

cracking, and (e) flank wear and built-up edge. Source: (a) Terms and definitions reproduced

with the permission of the International Organization for Standardization, ISO, copyright

remains with ISO. (b)-(e) Courtesy of Kennametal Inc.