Page 157 - Marks Calculation for Machine Design

P. 157

P1: Rakesh

January 4, 2005

14:16

Brown.cls

Brown˙C03

U.S. Customary ADVANCED LOADINGS SI/Metric 139

Step 4. As the minimum radial interface (δ min ) Step 4. As the minimum radial interface (δ min )

calculated from Step 2 is zero, the minimum calculated from Step 2 is very small, the mini-

interface pressure (p min ) is also zero. So, mum interface pressure (p min ) is

p min = 0 p min = 0

3.3 CONTACT LOADING

Contact loading occurs between machine elements such as rolling metal wheels, meshing

of gear teeth, and within the entire spectrum of bearings. The discussion on contact loading

will be divided into two main areas:

1. Spheres in contact

2. Cylinders in contact

In contact loading, an initial point (spheres) or line (cylinders) of contact develops into

an area of contact over which the load must be distributed. As these areas are typically very

small, the associated stresses can be quite large. The location of maximum stress can actually

occur below the surface of the machine element, causing catastrophic failure without prior

visible warning. For this reason, understanding the principles and stress equations that

follow are important to the machine designer.

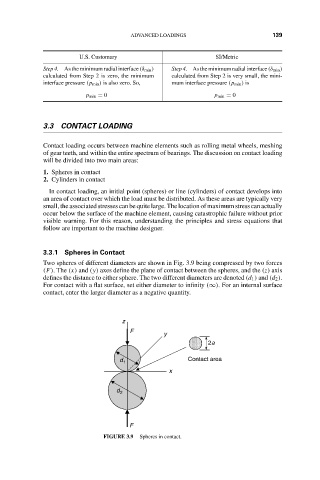

3.3.1 Spheres in Contact

Two spheres of different diameters are shown in Fig. 3.9 being compressed by two forces

(F). The (x) and (y) axes define the plane of contact between the spheres, and the (z) axis

defines the distance to either sphere. The two different diameters are denoted (d 1 ) and (d 2 ).

For contact with a flat surface, set either diameter to infinity (∞). For an internal surface

contact, enter the larger diameter as a negative quantity.

z

F

y

2a

d 1 Contact area

x

d 2

F

FIGURE 3.9 Spheres in contact.