Page 193 - Marks Calculation for Machine Design

P. 193

P1: Shibu

January 4, 2005

14:25

Brown.cls

Brown˙C04

U.S. Customary COMBINED LOADINGS SI/Metric 175

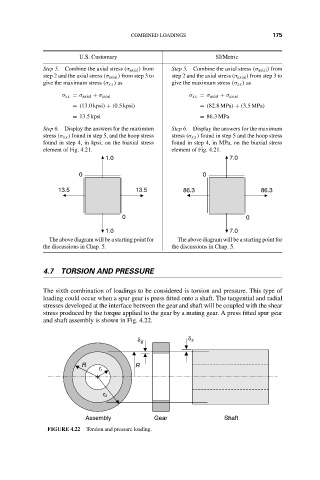

Step 5. Combine the axial stress (σ axial ) from Step 5. Combine the axial stress (σ axial ) from

step 2 and the axial stress (σ axial ) from step 3 to step 2 and the axial stress (σ axial ) from step 3 to

give the maximum stress (σ xx ) as give the maximum stress (σ xx ) as

σ xx = σ axial + σ axial σ xx = σ axial + σ axial

= (13.0 kpsi) + (0.5 kpsi) = (82.8MPa) + (3.5MPa)

= 13.5 kpsi = 86.3MPa

Step 6. Display the answers for the maximum Step 6. Display the answers for the maximum

stress (σ xx ) found in step 5, and the hoop stress stress (σ xx ) found in step 5 and the hoop stress

found in step 4, in kpsi, on the biaxial stress found in step 4, in MPa, on the biaxial stress

element of Fig. 4.21. element of Fig. 4.21.

1.0 7.0

0 0

13.5 13.5 86.3 86.3

0 0

1.0 7.0

The above diagram will be a starting point for The above diagram will be a starting point for

the discussions in Chap. 5. the discussions in Chap. 5.

4.7 TORSION AND PRESSURE

The sixth combination of loadings to be considered is torsion and pressure. This type of

loading could occur when a spur gear is press fitted onto a shaft. The tangential and radial

stresses developed at the interface between the gear and shaft will be coupled with the shear

stress produced by the torque applied to the gear by a mating gear. A press fitted spur gear

and shaft assembly is shown in Fig. 4.22.

δ s

δ g

R R

r i

r o

Assembly Gear Shaft

FIGURE 4.22 Torsion and pressure loading.