Page 198 - Marks Calculation for Machine Design

P. 198

P1: Shibu

January 4, 2005

Brown˙C04

Brown.cls

180

2pR

s t min = 14:25 2 STRENGTH OF MACHINES s t min

r − R 2

2

o

t max

0 s r min = 0 0 0 Axis

2Tr o

t max =

4

p r – R 4 t max

o

s t min s t min

Edge view Plan view

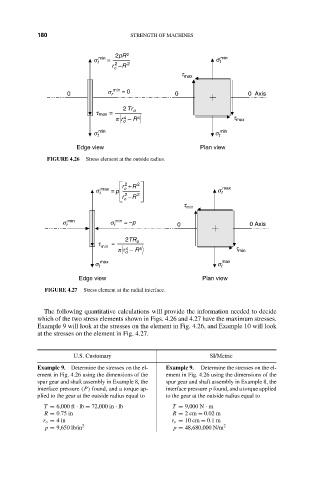

FIGURE 4.26 Stress element at the outside radius.

r + R 2 max

2

s t max = p o s t

2

r − R 2

o

t min

s r min s r min = –p 0 0 Axis

2TR

t = o

min

4

p r – R 4 t min

o

max max

s t s t

Edge view Plan view

FIGURE 4.27 Stress element at the radial interface.

The following quantitative calculations will provide the information needed to decide

which of the two stress elements shown in Figs. 4.26 and 4.27 have the maximum stresses.

Example 9 will look at the stresses on the element in Fig. 4.26, and Example 10 will look

at the stresses on the element in Fig. 4.27.

U.S. Customary SI/Metric

Example 9. Determine the stresses on the el- Example 9. Determine the stresses on the el-

ement in Fig. 4.26 using the dimensions of the ement in Fig. 4.26 using the dimensions of the

spur gear and shaft assembly in Example 8, the spur gear and shaft assembly in Example 8, the

interface pressure (P) found, and a torque ap- interface pressure p found, and a torque applied

plied to the gear at the outside radius equal to to the gear at the outside radius equal to

T = 6,000 ft · lb = 72,000 in · lb T = 9,000 N · m

R = 0.75 in R = 2cm = 0.02 m

r o = 4in r o = 10 cm = 0.1 m

p = 9,650 lb/in 2 p = 48,680,000 N/m 2