Page 190 - Marks Calculation for Machine Design

P. 190

P1: Shibu

January 4, 2005

Brown˙C04

Brown.cls

172

U.S. Customary 14:25 STRENGTH OF MACHINES SI/Metric

Step 4. Combine the shear stress due to the Step 4. Combine the shear stress due to the

torque (T AB ) from step 1 and the shear stress torque (T AB ) from step 1 and the shear stress

due to bending from step 3 using the expression due to bending from step 3 using the expression

in Eq. (4.13) to give in Eq. (4.13) to give

2 T AB 4 V 2 T AB 4 V

τ xy = + τ xy = +

π R 3 3 π R 2 π R 3 3 πR 2

= 3.8 kpsi + 0.2 kpsi = 4.0 kpsi = 36.7MPa + 1.5MPa = 38.2MPa

Step 5. Display the answer for the maximum Step 5. Display the answer for the maximum

shear stress (τ xy ) found in step 4, in kpsi, on the shear stress (τ xy ) found in step 4, in kpsi, on the

left stress element in Fig. 4.19. left stress element in Fig. 4.19.

0 0

4.0 38.2

0 0 0 0

4.0 38.2

0 0

As with the previous examples, this stress As with the previous examples, this stress

element diagram will be a starting point for the element diagram will be a starting point for the

discussions in Chap. 5. discussions in Chap. 5.

4.6 AXIAL AND PRESSURE

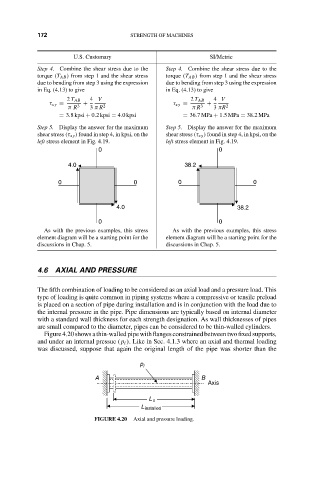

The fifth combination of loading to be considered as an axial load and a pressure load. This

type of loading is quite common in piping systems where a compressive or tensile preload

is placed on a section of pipe during installation and is in conjunction with the load due to

the internal pressure in the pipe. Pipe dimensions are typically based on internal diameter

with a standard wall thickness for each strength designation. As wall thicknesses of pipes

are small compared to the diameter, pipes can be considered to be thin-walled cylinders.

Figure4.20showsathin-walledpipewithflangesconstrainedbetweentwofixedsupports,

and under an internal pressue (p i ). Like in Sec. 4.1.3 where an axial and thermal loading

was discussed, suppose that again the original length of the pipe was shorter than the

p i

A B

Axis

L o

L installed

FIGURE 4.20 Axial and pressure loading.