Page 185 - Marks Calculation for Machine Design

P. 185

P1: Shibu

January 4, 2005

14:25

Brown˙C04

Brown.cls

167

COMBINED LOADINGS

4.5

TORSION AND BENDING

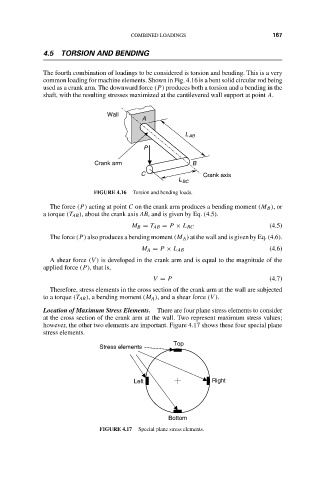

The fourth combination of loadings to be considered is torsion and bending. This is a very

common loading for machine elements. Shown in Fig. 4.16 is a bent solid circular rod being

used as a crank arm. The downward force (P) produces both a torsion and a bending in the

shaft, with the resulting stresses maximized at the cantilevered wall support at point A.

Wall

A

L AB

P

Crank arm B

C Crank axis

L

BC

FIGURE 4.16 Torsion and bending loads.

The force (P) acting at point C on the crank arm produces a bending moment (M B ),or

a torque (T AB ), about the crank axis AB, and is given by Eq. (4.5).

M B = T AB = P × L BC (4.5)

The force (P) also produces a bending moment (M A ) at the wall and is given by Eq. (4.6).

M A = P × L AB (4.6)

A shear force (V ) is developed in the crank arm and is equal to the magnitude of the

applied force (P), that is,

V = P (4.7)

Therefore, stress elements in the cross section of the crank arm at the wall are subjected

to a torque (T AB ), a bending moment (M A ), and a shear force (V ).

Location of Maximum Stress Elements. There are four plane stress elements to consider

at the cross section of the crank arm at the wall. Two represent maximum stress values;

however, the other two elements are important. Figure 4.17 shows these four special plane

stress elements.

Top

Stress elements

Left Right

Bottom

FIGURE 4.17 Special plane stress elements.