Page 378 - Marks Calculation for Machine Design

P. 378

P1: Sanjay

January 4, 2005

Brown˙C08

Brown.cls

360

U.S. Customary 15:14 APPLICATION TO MACHINES SI/Metric

Step 6. Substitute the average stress (σ avg ) Step 6. Substitute the average stress (σ avg )

from step 4 and the maximum shear stress from step 4 and the maximum shear stress

(τ max ) from step 5 in Eq. (5.15) to determine (τ max ) from step 5 in Eq. (5.15) to determine

the principal stress (σ 1 ) as the principal stress (σ 1 ) as

σ 1 = σ avg + τ max σ 1 = σ avg + τ max

= (7.15 kpsi) + (7.18 kpsi) = (47.8MPa) + (48.0MPa)

= 14.32 kpsi = 95.8MPa

Note that the contribution from the shear stress (τ shear ) in the calculations for the principal

stress (σ 1 ) and the maximum shear stress (τ max ) was almost negligible compared to the

normal stress (σ bending ). This is typical of these kinds of weld joint configurations and

loadings.

8.3.4 Fillet Welds Treated as Lines

In Examples 1 through 4, the weld throat (H) was specified as part of the given information,

determined from a weld size (t). However, in practice the weld size may be the primary

unknown. Therefore, it is convenient to set the weld throat (H) equal to unity (1) in the

expressions for the weld area, (A butt ) or (A fillet ), the polar moment of inertia (J group ), and

the moment of inertia (I group ) so that in the calculations for the stresses the units are stress

times a unit width, that is, (kpsi-in) or (MPa-m). Once an appropriate weld strength (S weld )

is specified, dividing this strength into the calculated stress will give a value for the size of

weld throat (H), from which a weld size (t) can be found.

There are sets of tabulated formulas for the weld areas and moments of inertia of various

weld configurations in any number of references, such as Marks’ Standard Handbook for

Mechanical Engineers. However, to show how setting the weld throat (H) to unity (1)

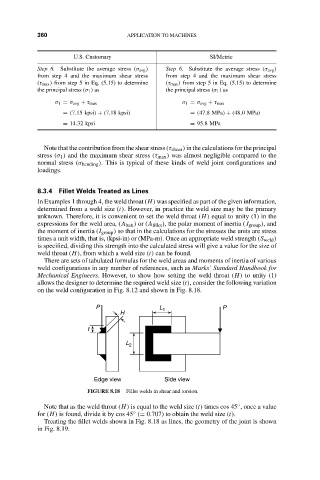

allows the designer to determine the required weld size (t), consider the following variation

on the weld configuration in Fig. 8.12 and shown in Fig. 8.18.

P L 1 P

H

t

L 2

Edge view Side view

FIGURE 8.18 Fillet welds in shear and torsion.

Note that as the weld throat (H) is equal to the weld size (t) times cos 45 , once a value

◦

for (H) is found, divide it by cos 45 (= 0.707) to obtain the weld size (t).

◦

Treating the fillet welds shown in Fig. 8.18 as lines, the geometry of the joint is shown

in Fig. 8.19.