Page 376 - Marks Calculation for Machine Design

P. 376

P1: Sanjay

15:14

January 4, 2005

Brown.cls

Brown˙C08

APPLICATION TO MACHINES

358

H

t P

×

P Top view

P

L

t L o

Front view Side view

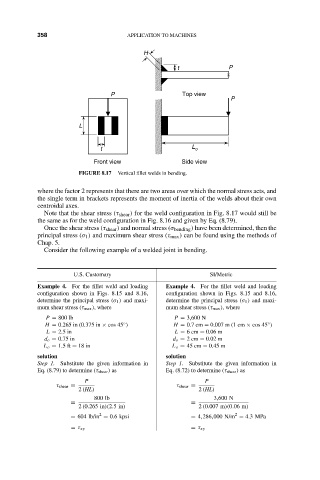

FIGURE 8.17 Vertical fillet welds in bending.

where the factor 2 represents that there are two areas over which the normal stress acts, and

the single term in brackets represents the moment of inertia of the welds about their own

centroidal axes.

Note that the shear stress (τ shear ) for the weld configuration in Fig. 8.17 would still be

the same as for the weld configuration in Fig. 8.16 and given by Eq. (8.79).

Once the shear stress (τ shear ) and normal stress (σ bending ) have been determined, then the

principal stress (σ 1 ) and maximum shear stress (τ max ) can be found using the methods of

Chap. 5.

Consider the following example of a welded joint in bending.

U.S. Customary SI/Metric

Example 4. For the fillet weld and loading Example 4. For the fillet weld and loading

configuration shown in Figs. 8.15 and 8.16, configuration shown in Figs. 8.15 and 8.16,

determine the principal stress (σ 1 ) and maxi- determine the principal stress (σ 1 ) and maxi-

mum shear stress (τ max ), where mum shear stress (τ max ), where

P = 800 lb P = 3,600 N

◦

H = 0.265 in (0.375 in × cos 45 ) H = 0.7 cm = 0.007 m (1 cm × cos 45 )

◦

L = 2.5 in L = 6cm = 0.06 m

d o = 0.75 in d o = 2cm = 0.02 m

L o = 1.5 ft = 18 in L o = 45 cm = 0.45 m

solution solution

Step 1. Substitute the given information in Step 1. Substitute the given information in

Eq. (8.79) to determine (τ shear ) as Eq. (8.72) to determine (τ shear ) as

P P

τ shear = τ shear =

2 (HL) 2 (HL)

800 lb 3,600 N

= =

2 (0.265 in)(2.5in) 2 (0.007 m)(0.06 m)

2

2

= 604 lb/in = 0.6 kpsi = 4,286,000 N/m = 4.3MPa

= τ xy = τ xy