Page 206 - Materials Science and Engineering An Introduction

P. 206

178 • Chapter 6 / Mechanical Properties of Metals

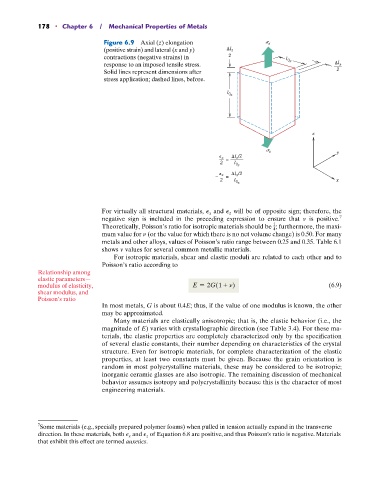

Figure 6.9 Axial (z) elongation z

(positive strain) and lateral (x and y) l z

contractions (negative strains) in 2 l

response to an imposed tensile stress. 0 x l x

Solid lines represent dimensions after 2

stress application; dashed lines, before.

l 0 z

z

z y

z = l z /2

2 l

0 z

x l x /2

– =

2 l x

0 x

will be of opposite sign; therefore, the

For virtually all structural materials, P x and P z

7

negative sign is included in the preceding expression to ensure that v is positive.

1

Theoretically, Poisson’s ratio for isotropic materials should be ; furthermore, the maxi-

4

mum value for n (or the value for which there is no net volume change) is 0.50. For many

metals and other alloys, values of Poisson’s ratio range between 0.25 and 0.35. Table 6.1

shows v values for several common metallic materials.

For isotropic materials, shear and elastic moduli are related to each other and to

Poisson’s ratio according to

Relationship among

elastic parameters—

modulus of elasticity, E = 2G(1 + n) (6.9)

shear modulus, and

Poisson’s ratio

In most metals, G is about 0.4E; thus, if the value of one modulus is known, the other

may be approximated.

Many materials are elastically anisotropic; that is, the elastic behavior (i.e., the

magnitude of E) varies with crystallographic direction (see Table 3.4). For these ma-

terials, the elastic properties are completely characterized only by the specification

of several elastic constants, their number depending on characteristics of the crystal

structure. Even for isotropic materials, for complete characterization of the elastic

properties, at least two constants must be given. Because the grain orientation is

random in most polycrystalline materials, these may be considered to be isotropic;

inorganic ceramic glasses are also isotropic. The remaining discussion of mechanical

behavior assumes isotropy and polycrystallinity because this is the character of most

engineering materials.

7 Some materials (e.g., specially prepared polymer foams) when pulled in tension actually expand in the transverse

direction. In these materials, both P x and P z of Equation 6.8 are positive, and thus Poisson’s ratio is negative. Materials

that exhibit this effect are termed auxetics.