Page 247 - Materials Science and Engineering An Introduction

P. 247

7.2 Basic Concepts • 219

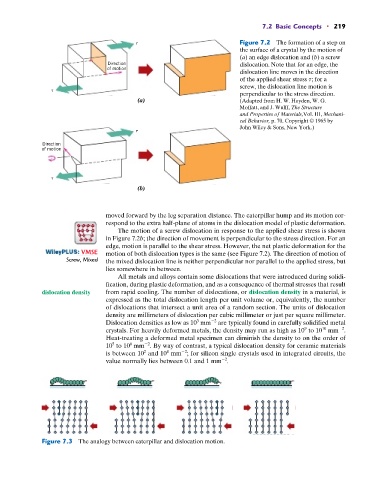

Figure 7.2 The formation of a step on

the surface of a crystal by the motion of

(a) an edge dislocation and (b) a screw

Direction dislocation. Note that for an edge, the

of motion

dislocation line moves in the direction

of the applied shear stress t; for a

screw, the dislocation line motion is

perpendicular to the stress direction.

(a) (Adapted from H. W. Hayden, W. G.

Moffatt, and J. Wulff, The Structure

and Properties of Materials,Vol. III, Mechani-

cal Behavior, p. 70. Copyright © 1965 by

John Wiley & Sons, New York.)

Direction

of motion

(b)

moved forward by the leg separation distance. The caterpillar hump and its motion cor-

respond to the extra half-plane of atoms in the dislocation model of plastic deformation.

The motion of a screw dislocation in response to the applied shear stress is shown

in Figure 7.2b; the direction of movement is perpendicular to the stress direction. For an

edge, motion is parallel to the shear stress. However, the net plastic deformation for the

: VMSE motion of both dislocation types is the same (see Figure 7.2). The direction of motion of

Screw, Mixed the mixed dislocation line is neither perpendicular nor parallel to the applied stress, but

lies somewhere in between.

All metals and alloys contain some dislocations that were introduced during solidi-

fication, during plastic deformation, and as a consequence of thermal stresses that result

dislocation density from rapid cooling. The number of dislocations, or dislocation density in a material, is

expressed as the total dislocation length per unit volume or, equivalently, the number

of dislocations that intersect a unit area of a random section. The units of dislocation

density are millimeters of dislocation per cubic millimeter or just per square millimeter.

3

2

Dislocation densities as low as 10 mm are typically found in carefully solidified metal

2

9

10

crystals. For heavily deformed metals, the density may run as high as 10 to 10 mm .

Heat-treating a deformed metal specimen can diminish the density to on the order of

2

6

5

10 to 10 mm . By way of contrast, a typical dislocation density for ceramic materials

4

2

is between 10 and 10 mm ; for silicon single crystals used in integrated circuits, the

2

2

value normally lies between 0.1 and 1 mm .

Figure 7.3 The analogy between caterpillar and dislocation motion.