Page 358 - Materials Science and Engineering An Introduction

P. 358

330 • Chapter 9 / Phase Diagrams

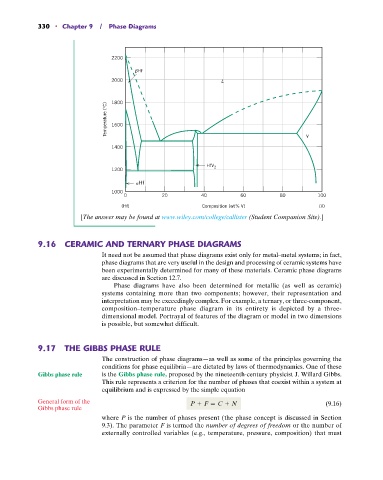

2200

Hf

2000 L

Temperature (°C) 1800

1600

1400 V

HfV

1200 2

Hf

1000

0 20 40 60 80 100

(Hf) Composition (wt% V) (V)

[The answer may be found at www.wiley.com/college/callister (Student Companion Site).]

9.16 CERAMIC AND TERNARY PHASE DIAGRAMS

It need not be assumed that phase diagrams exist only for metal–metal systems; in fact,

phase diagrams that are very useful in the design and processing of ceramic systems have

been experimentally determined for many of these materials. Ceramic phase diagrams

are discussed in Section 12.7.

Phase diagrams have also been determined for metallic (as well as ceramic)

systems containing more than two components; however, their representation and

interpretation may be exceedingly complex. For example, a ternary, or three-component,

composition–temperature phase diagram in its entirety is depicted by a three-

dimensional model. Portrayal of features of the diagram or model in two dimensions

is possible, but somewhat difficult.

9.17 THE GIBBS PHASE RULE

The construction of phase diagrams—as well as some of the principles governing the

conditions for phase equilibria—are dictated by laws of thermodynamics. One of these

Gibbs phase rule is the Gibbs phase rule, proposed by the nineteenth-century physicist J. Willard Gibbs.

This rule represents a criterion for the number of phases that coexist within a system at

equilibrium and is expressed by the simple equation

General form of the P + F = C + N (9.16)

Gibbs phase rule

where P is the number of phases present (the phase concept is discussed in Section

9.3). The parameter F is termed the number of degrees of freedom or the number of

externally controlled variables (e.g., temperature, pressure, composition) that must