Page 357 - Materials Science and Engineering An Introduction

P. 357

9.15 Congruent Phase Transformations • 329

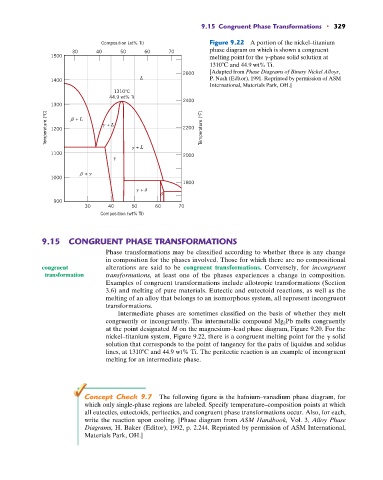

Composition (at% Ti) Figure 9.22 A portion of the nickel–titanium

phase diagram on which is shown a congruent

30 40 50 60 70

1500 melting point for the g-phase solid solution at

1310 C and 44.9 wt% Ti.

[Adapted from Phase Diagrams of Binary Nickel Alloys,

2600

L P. Nash (Editor), 1991. Reprinted by permission of ASM

1400

International, Materials Park, OH.]

1310°C

44.9 wt% Ti

2400

1300

Temperature (°C) 1200 + L + L 2200 Temperature (°F)

+ L

1100 2000

+

1000

1800

+

900

30 40 50 60 70

Composition (wt% Ti)

9.15 CONGRUENT PHASE TRANSFORMATIONS

Phase transformations may be classified according to whether there is any change

in composition for the phases involved. Those for which there are no compositional

congruent alterations are said to be congruent transformations. Conversely, for incongruent

transformation transformations, at least one of the phases experiences a change in composition.

Examples of congruent transformations include allotropic transformations (Section

3.6) and melting of pure materials. Eutectic and eutectoid reactions, as well as the

melting of an alloy that belongs to an isomorphous system, all represent incongruent

transformations.

Intermediate phases are sometimes classified on the basis of whether they melt

congruently or incongruently. The intermetallic compound Mg 2 Pb melts congruently

at the point designated M on the magnesium–lead phase diagram, Figure 9.20. For the

nickel–titanium system, Figure 9.22, there is a congruent melting point for the g solid

solution that corresponds to the point of tangency for the pairs of liquidus and solidus

lines, at 1310 C and 44.9 wt% Ti. The peritectic reaction is an example of incongruent

melting for an intermediate phase.

Concept Check 9.7 The following figure is the hafnium–vanadium phase diagram, for

which only single-phase regions are labeled. Specify temperature–composition points at which

all eutectics, eutectoids, peritectics, and congruent phase transformations occur. Also, for each,

write the reaction upon cooling. [Phase diagram from ASM Handbook, Vol. 3, Alloy Phase

Diagrams, H. Baker (Editor), 1992, p. 2.244. Reprinted by permission of ASM International,

Materials Park, OH.]