Page 149 - Mechanical design of microresonators _ modeling and applications

P. 149

0-07-145538-8_CH03_148_08/30/05

Microhinges and Microcantilevers: Lumped-Parameter Modeling and Design

148 Chapter Three

5

0.5

r ω

1

0.00001 c2

c1

0.00001

0.5

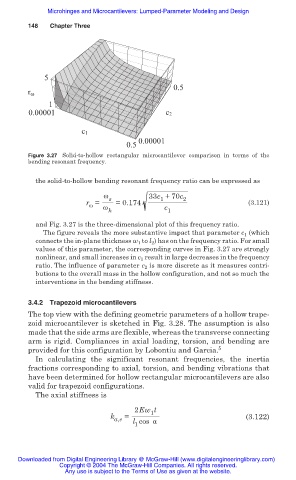

Figure 3.27 Solid-to-hollow rectangular microcantilever comparison in terms of the

bending resonant frequency.

the solid-to-hollow bending resonant frequency ratio can be expressed as

Ȧ s 33c +70c 2

1

r = Ȧ =0.174 (3.121)

Ȧ

h c 1

and Fig. 3.27 is the three-dimensional plot of this frequency ratio.

The figure reveals the more substantive impact that parameter c 1 (which

connects the in-plane thickness w 1 to l 2 ) has on the frequency ratio. For small

values of this parameter, the corresponding curves in Fig. 3.27 are strongly

nonlinear, and small increases in c 1 result in large decreases in the frequency

ratio. The influence of parameter c 2 is more discrete as it measures contri-

butions to the overall mass in the hollow configuration, and not so much the

interventions in the bending stiffness.

3.4.2 Trapezoid microcantilevers

The top view with the defining geometric parameters of a hollow trape-

zoid microcantilever is sketched in Fig. 3.28. The assumption is also

made that the side arms are flexible, whereas the transverse connecting

arm is rigid. Compliances in axial loading, torsion, and bending are

provided for this configuration by Lobontiu and Garcia. 5

In calculating the significant resonant frequencies, the inertia

fractions corresponding to axial, torsion, and bending vibrations that

have been determined for hollow rectangular microcantilevers are also

valid for trapezoid configurations.

The axial stiffness is

2Ew t

1

k = (3.122)

a,e l cos Į

1

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.