Page 812 - Mechanical Engineers' Handbook (Volume 2)

P. 812

5 Multiloop NN Feedback Control Structures 803

of inexactly known or changing flexible mode frequencies. An observer can be used to avoid

strain rate measurements.

In many industrial or aerospace designs, flexibility effects are limited by restricting the

speed of motion of the system. This limits performance. By contrast, using the singular

perturbation NN controller, a flexible system can far outperform a rigid system in terms of

speed of response. The key is to use the flexibility effects to speed up the response in much

the same manner as the cracking of a whip. That is, the flexibility effects of advanced

structures are not merely a debility that must be overcome, but they offer the possibility of

improved performance over rigid structures if they are suitably controlled. By exploiting

recent advances in materials, such as piezoelectric materials, further improved performance

is attainable for the so-called smart material flexible robots. 20b

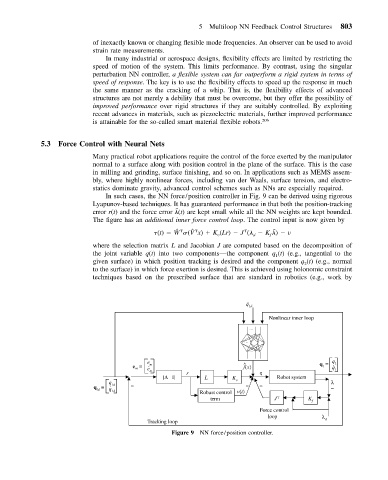

5.3 Force Control with Neural Nets

Many practical robot applications require the control of the force exerted by the manipulator

normal to a surface along with position control in the plane of the surface. This is the case

in milling and grinding, surface finishing, and so on. In applications such as MEMS assem-

bly, where highly nonlinear forces, including van der Waals, surface tension, and electro-

statics dominate gravity, advanced control schemes such as NNs are especially required.

In such cases, the NN force/position controller in Fig. 9 can be derived using rigorous

Lyapunov-based techniques. It has guaranteed performance in that both the position-tracking

˜

error r(t) and the force error

(t) are kept small while all the NN weights are kept bounded.

The figure has an additional inner force control loop. The control input is now given by

˜

ˆ

ˆ

T

T

(t) W (Vx) K (Lr) J (

K

) v

T

v

d

f

where the selection matrix L and Jacobian J are computed based on the decomposition of

the joint variable q(t) into two components—the component q (t) (e.g., tangential to the

1

given surface) in which position tracking is desired and the component q (t) (e.g., normal

2

to the surface) in which force exertion is desired. This is achieved using holonomic constraint

techniques based on the prescribed surface that are standard in robotics (e.g., work by

q ¨

1d 1 1

Nonlinear r inner loop

N o nline a

e ^ ^ q = . 1 . 1 . 1 . q 1

=

=

=

m e = = e m . . . f(x) 1 1 1 1 q

=

()

m r τ τ 1 1 1 1

[Λ I] L K Robot bot system

Ro

[Λ I]

q v λ λ

q = = = = q . 1d 1 . 1 . 1 .

d 1

()

u

1d 1 1 1 Robust st control v(t)

b

Ro

term J T K f

F Force rce control

o

loop λ λ

r

T Tracking ng loop d

acki

Figure 9 NN force/position controller.