Page 211 - Mechanics of Microelectromechanical Systems

P. 211

198 Chapter 4

In the majority of MEMS applications‚ the actuation force or the sensing

signal are insufficient when only one pair of moving-fixed parts are being

utilized. The practical solution to this problem is to couple several pairs of

such mating members in a comb-type configuration. Figure 4.19 sketches an

interdigitated pair with the main geometric parameters. The motion about

direction 1 in this figure is usually referred to as parallel-plate whereas the

other possible motion‚ about direction 2‚ is generally named comb-finger

motion. However‚ the interdigitated designs are used for both motions‚ and

therefore‚ in order to avoid confusion‚ the alternative denominations of

transverse and longitudinal will be used to indicate motions about the 1 and

2 directions‚ respectively.

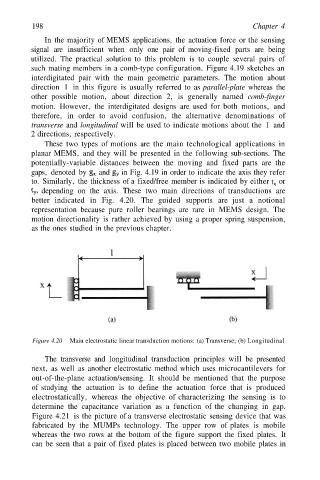

These two types of motions are the main technological applications in

planar MEMS‚ and they will be presented in the following sub-sections. The

potentially-variable distances between the moving and fixed parts are the

gaps‚ denoted by and in Fig. 4.19 in order to indicate the axis they refer

to. Similarly‚ the thickness of a fixed/free member is indicated by either or

depending on the axis. These two main directions of transductions are

better indicated in Fig. 4.20. The guided supports are just a notional

representation because pure roller bearings are rare in MEMS design. The

motion directionality is rather achieved by using a proper spring suspension‚

as the ones studied in the previous chapter.

Figure 4.20 Main electrostatic linear transduction motions: (a) Transverse; (b) Longitudinal

The transverse and longitudinal transduction principles will be presented

next‚ as well as another electrostatic method which uses microcantilevers for

out-of-the-plane actuation/sensing. It should be mentioned that the purpose

of studying the actuation is to define the actuation force that is produced

electrostatically‚ whereas the objective of characterizing the sensing is to

determine the capacitance variation as a function of the changing in gap.

Figure 4.21 is the picture of a transverse electrostatic sensing device that was

fabricated by the MUMPs technology. The upper row of plates is mobile

whereas the two rows at the bottom of the figure support the fixed plates. It

can be seen that a pair of fixed plates is placed between two mobile plates in