Page 73 -

P. 73

62 2 Extremely Short-External-Cavity Laser Diode

(a) (b)

access codes access codes

WA WA

CLK CLK

WB WB

Laser Beam

1.6 mm

unique distance

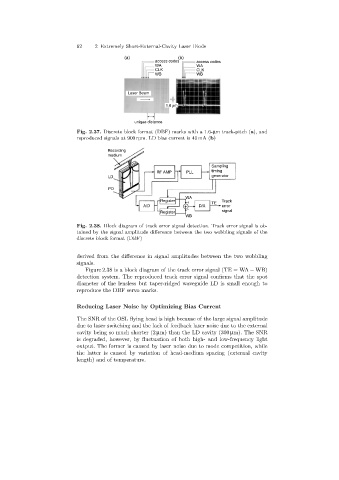

Fig. 2.37. Discrete block format (DBF)marks with a 1.6-µm track-pitch (a),and

reproduced signals at 900 rpm. LD bias current is 40 mA (b)

Recording

medium

Sampling

RF AMP PLL timing

LD generator

PD

WA

Register + TE Track

A/D D/A error

-

Register signal

WB

Fig. 2.38. Block diagram of track error signal detection. Track error signal is ob-

tained by the signal amplitude difference between the two wobbling signals of the

discrete block format (DBF)

derived from the difference in signal amplitudes between the two wobbling

signals.

Figure 2.38 is a block diagram of the track error signal (TE = WA − WB)

detection system. The reproduced track error signal confirms that the spot

diameter of the lensless but taper-ridged waveguide LD is small enough to

reproduce the DBF servo marks.

Reducing Laser Noise by Optimizing Bias Current

The SNR of the OSL flying head is high because of the large signal amplitude

due to laser switchingand the lack of feedback laser noise due to the external

cavity beingso much shorter (2 µm) than the LD cavity (300 µm). The SNR

is degraded, however, by fluctuation of both high- and low-frequency light

output. The former is caused by laser noise due to mode competition, while

the latter is caused by variation of head-medium spacing(external cavity

length) and of temperature.