Page 311 - A Practical Guide from Design Planning to Manufacturing

P. 311

Semiconductor Manufacturing 281

Photoresist

Spin-on Chrome

and

soft bake

Quartz

E-beam

Write

and Chrome

develop and

hard bake Quartz

Etch

and

strip Quartz

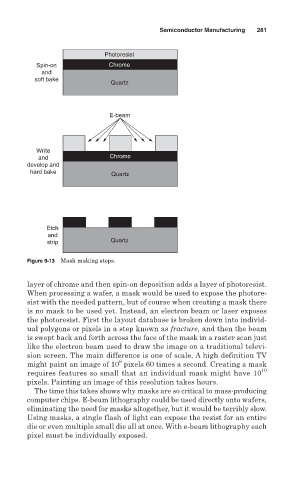

Figure 9-13 Mask making steps.

layer of chrome and then spin-on deposition adds a layer of photoresist.

When processing a wafer, a mask would be used to expose the photore-

sist with the needed pattern, but of course when creating a mask there

is no mask to be used yet. Instead, an electron beam or laser exposes

the photoresist. First the layout database is broken down into individ-

ual polygons or pixels in a step known as fracture, and then the beam

is swept back and forth across the face of the mask in a raster scan just

like the electron beam used to draw the image on a traditional televi-

sion screen. The main difference is one of scale. A high definition TV

6

might paint an image of 10 pixels 60 times a second. Creating a mask

requires features so small that an individual mask might have 10 10

pixels. Painting an image of this resolution takes hours.

The time this takes shows why masks are so critical to mass-producing

computer chips. E-beam lithography could be used directly onto wafers,

eliminating the need for masks altogether, but it would be terribly slow.

Using masks, a single flash of light can expose the resist for an entire

die or even multiple small die all at once. With e-beam lithography each

pixel must be individually exposed.