Page 302 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 302

282 MICROSENSORS

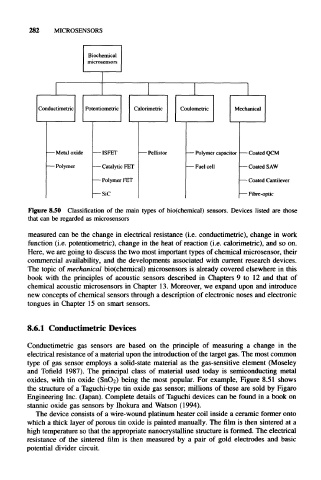

• Metal oxide -ISFET — Pellistor • Polymer capacitor — Coated QCM

• Polymer • Catalytic FET Fuel cell Coated SAW

Polymer FET — Coated Cantilever

SiC — Fibre-optic

Figure 8.50 Classification of the main types of bio(chemical) sensors. Devices listed are those

that can be regarded as microsensors

measured can be the change in electrical resistance (i.e. conductimetric), change in work

function (i.e. potentiometric), change in the heat of reaction (i.e. calorimetric), and so on.

Here, we are going to discuss the two most important types of chemical microsensor, their

commercial availability, and the developments associated with current research devices.

The topic of mechanical bio(chemical) microsensors is already covered elsewhere in this

book with the principles of acoustic sensors described in Chapters 9 to 12 and that of

chemical acoustic microsensors in Chapter 13. Moreover, we expand upon and introduce

new concepts of chemical sensors through a description of electronic noses and electronic

tongues in Chapter 15 on smart sensors.

8.6.1 Conductimetric Devices

Conductimetric gas sensors are based on the principle of measuring a change in the

electrical resistance of a material upon the introduction of the target gas. The most common

type of gas sensor employs a solid-state material as the gas-sensitive element (Moseley

and Tofield 1987). The principal class of material used today is semiconducting metal

oxides, with tin oxide (SnO 2) being the most popular. For example, Figure 8.51 shows

the structure of a Taguchi-type tin oxide gas sensor; millions of these are sold by Figaro

Engineering Inc. (Japan). Complete details of Taguchi devices can be found in a book on

stannic oxide gas sensors by Ihokura and Watson (1994).

The device consists of a wire-wound platinum heater coil inside a ceramic former onto

which a thick layer of porous tin oxide is painted manually. The film is then sintered at a

high temperature so that the appropriate nanocrystalline structure is formed. The electrical

resistance of the sintered film is then measured by a pair of gold electrodes and basic

potential divider circuit.