Page 305 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 305

BIO(CHEMICAL) SENSORS 285

Table 8.17 Some commercial gas sensors based on semiconducting metal oxide

Manufacturer Model Material Measurand Range (Power Cost a

(PPM) mW) (euro)

Figaro Inc. (Japan) TGS842 Doped SnO 2 Methane 500-10000 835 13

Figaro Inc. (Japan) TGS825 Doped SnO 2 Hydrogen 5-100 660 50

sulfide

Figaro Inc. (Japan) TGS800 Doped SnO 2 Air quality <10 660 13

(smoke)

FiS (Japan) SB5000 Doped SnO 2 Toxic gas - 10-1000 120 13

CO

FiS (Japan) SP1100 Doped SnO 2 Hydrocarbons 10-1000 400 15

b

Capteur (UK) LGS09 Undoped Chlorine 0-5 650 25

oxide

Capteur (UK) LGS21 Undoped Ozone 0-0.3 800 25

oxide

a

Price for 1 to 9 units 1 euro is $1.1 here

part of First Technology plc (UK)

Table 8.17 lists some tin oxide gas sensors that are commercially available together

with their properties.

The requirement to run this type of gas sensor at a high temperature causes the power

consumption of about 0.8 W of a Taguchi-type device to be a problem for handheld

units. Consequently, there has been considerable effort since the late 1980s toward the

use of silicon planar technology to make micropower gas sensors in volume at low cost

(less than €5). Designs of silicon planar microhotplates started to appear around the

late 1980s when Demarne and Grisel (1988) and later Corcoran et al. (1993) reported

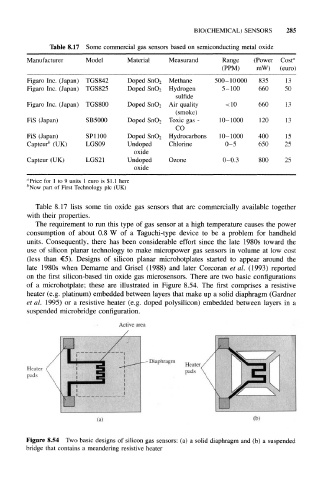

on the first silicon-based tin oxide gas microsensors. There are two basic configurations

of a microhotplate; these are illustrated in Figure 8.54. The first comprises a resistive

heater (e.g. platinum) embedded between layers that make up a solid diaphragm (Gardner

et al. 1995) or a resistive heater (e.g. doped polysilicon) embedded between layers in a

suspended microbridge configuration.

Figure 8.54 Two basic designs of silicon gas sensors: (a) a solid diaphragm and (b) a suspended

bridge that contains a meandering resistive heater