Page 308 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 308

288 MICROSENSORS

7. Before KOH anisotropic etching, the topside protection resist had to be processed.

The wafers were held onto a spinner by a vacuum and a layer of Shipley Microposit

1813 23 was spin-coated over the wafers. This protecting layer was then photolitho-

graphically patterned with Mask 5 to expose the active diaphragm area and the four

contact pads. The photoresist was hard-baked for 1 hour at 180 °C after developing,

which made it more resistant to chemical attack. Clearly, the resist will not stand

up to attack by organic solvents or high temperatures. This layer has been replaced

recently by plasma-enhanced chemical vapour deposition (PECVD) nitride, which

permits the definition of a precise gas-sensitive area above the sensing electrodes.

Moreover, the nitride passivation layer can withstand the high operating tempera-

tures created by the heater.

8. The final processing stage was a KOH anisotropic bulk back-etch that creates the

diaphragm (membrane) structure and a thermal SiO 2 as an etch stop on the topside.

To prevent the wafer topside from being exposed to the etchants, the wafer was

mounted in a suitable holder during etching.

9. The back-etch also opened up V-grooves (not shown) in the wafer that allows the

wafer to be easily snapped up into individual silicon dies. This method is a much

more gentle a method than dicing up with a diamond saw.

24

10. Finally, the gas-sensitive layer is drop-deposited across the electrodes and sintered .

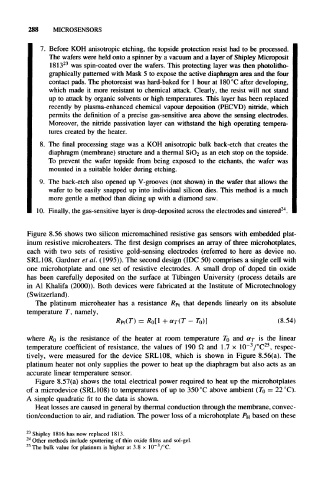

Figure 8.56 shows two silicon micromachined resistive gas sensors with embedded plat-

inum resistive microheaters. The first design comprises an array of three microhotplates,

each with two sets of resistive gold-sensing electrodes (referred to here as device no.

SRL 108, Gardner et al. (1995)). The second design (IDC 50) comprises a single cell with

one microhotplate and one set of resistive electrodes. A small drop of doped tin oxide

has been carefully deposited on the surface at Tubingen University (process details are

in Al Khalifa (2000)). Both devices were fabricated at the Institute of Microtechnology

(Switzerland).

The platinum microheater has a resistance R Pt that depends linearly on its absolute

temperature T, namely,

= R 0[l + a T(T - TQ)] (8.54)

where R 0 is the resistance of the heater at room temperature T 0 and UT is the linear

25

3

temperature coefficient of resistance, the values of 190 SI and 1.7 x 10~ /°C , respec-

tively, were measured for the device SRL108, which is shown in Figure 8.56(a). The

platinum heater not only supplies the power to heat up the diaphragm but also acts as an

accurate linear temperature sensor.

Figure 8.57(a) shows the total electrical power required to heat up the microhotplates

C

of a microdevice (SRL108) to temperatures of up to 350 °C above ambient (T 0 = 22 C).

A simple quadratic fit to the data is shown.

Heat losses are caused in general by thermal conduction through the membrane, convec-

tion/conduction to air, and radiation. The power loss of a microhotplate P H based on these

23

Shipley 1816 has now replaced 1813.

24

Other methods include sputtering of thin oxide films and sol-gel.

25 -3

The bulk value for platinum is higher at 3.8 x 10 /°C.