Page 307 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 307

BIO(CHEMICAL) SENSORS 287

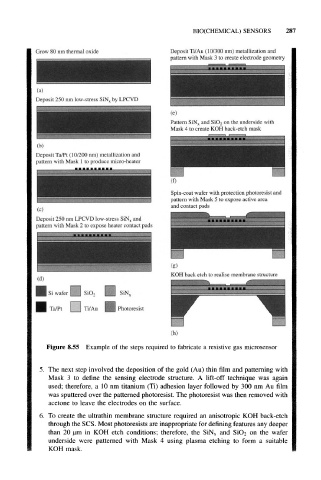

Figure 8.55 Example of the steps required to fabricate a resistive gas microsensor

5. The next step involved the deposition of the gold (Au) thin film and patterning with

Mask 3 to define the sensing electrode structure. A lift-off technique was again

used; therefore, a 10 nm titanium (Ti) adhesion layer followed by 300 nm Au film

was sputtered over the patterned photoresist. The photoresist was then removed with

acetone to leave the electrodes on the surface.

6. To create the ultrathin membrane structure required an anisotropic KOH back-etch

through the SCS. Most photoresists are inappropriate for defining features any deeper

than 20 urn in KOH etch conditions; therefore, the SiN x and SiO 2 on the wafer

underside were patterned with Mask 4 using plasma etching to form a suitable

KOH mask.