Page 303 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 303

BIO(CHEMICAL) SENSORS 283

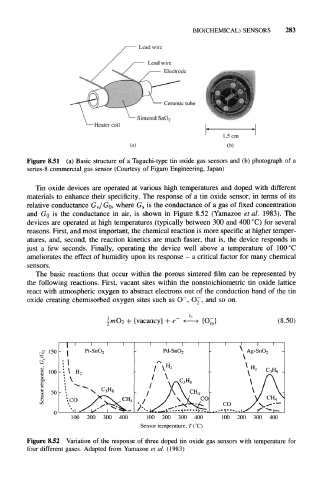

Figure 8.51 (a) Basic structure of a Taguchi-type tin oxide gas sensors and (b) photograph of a

series-8 commercial gas sensor (Courtesy of Figaro Engineering, Japan)

Tin oxide devices are operated at various high temperatures and doped with different

materials to enhance their specificity. The response of a tin oxide sensor, in terms of its

is the conductance of a gas of fixed concentration

relative conductance G s/G 0, where G s

and GO is the conductance in air, is shown in Figure 8.52 (Yamazoe et al. 1983). The

devices are operated at high temperatures (typically between 300 and 400 °C) for several

reasons. First, and most important, the chemical reaction is more specific at higher temper-

atures, and, second, the reaction kinetics are much faster, that is, the device responds in

just a few seconds. Finally, operating the device well above a temperature of 100 °C

ameliorates the effect of humidity upon its response - a critical factor for many chemical

sensors.

The basic reactions that occur within the porous sintered film can be represented by

the following reactions. First, vacant sites within the nonstoichiometric tin oxide lattice

react with atmospheric oxygen to abstract electrons out of the conduction band of the tin

-

oxide creating chemisorbed oxygen sites such as O , O 2, and so on.

+ {vacancy} + e~ (8.50)

Pd-SnO,

100

9 50

CO

..-•I---

100 200 300 400 100 200 300 400 100 200 300 400

Sensor temperature, 7'(°C)

Figure 8.52 Variation of the response of three doped tin oxide gas sensors with temperature for

four different gases. Adapted from Yamazoe et al. (1983)