Page 326 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 326

306 INTRODUCTION TO SAW DEVICES

models can be run with commercial SPICE software, which helps in the design of better

acoustic microtransducers.

9.3 THE PIEZOELECTRIC EFFECT

Piezoelectric crystals play a dominant role in the communications and electronics industry

where they are commonly used as filters, precision timers, and for frequency control in

oscillator circuits (Mason 1942). The piezoelectric effect can be demonstrated by applying

either a compressive or tensile stress to the opposite faces of a piezoelectric crystal.

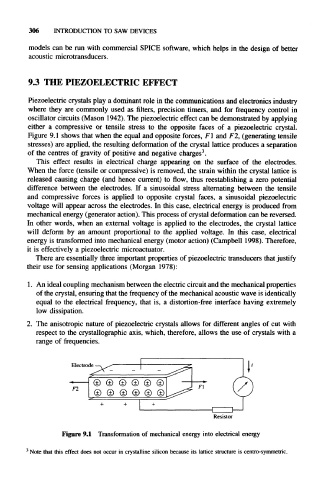

Figure 9.1 shows that when the equal and opposite forces, F1 and F2, (generating tensile

stresses) are applied, the resulting deformation of the crystal lattice produces a separation

3

of the centres of gravity of positive and negative charges .

This effect results in electrical charge appearing on the surface of the electrodes.

When the force (tensile or compressive) is removed, the strain within the crystal lattice is

released causing charge (and hence current) to flow, thus reestablishing a zero potential

difference between the electrodes. If a sinusoidal stress alternating between the tensile

and compressive forces is applied to opposite crystal faces, a sinusoidal piezoelectric

voltage will appear across the electrodes. In this case, electrical energy is produced from

mechanical energy (generator action). This process of crystal deformation can be reversed.

In other words, when an external voltage is applied to the electrodes, the crystal lattice

will deform by an amount proportional to the applied voltage. In this case, electrical

energy is transformed into mechanical energy (motor action) (Campbell 1998). Therefore,

it is effectively a piezoelectric microactuator.

There are essentially three important properties of piezoelectric transducers that justify

their use for sensing applications (Morgan 1978):

1. An ideal coupling mechanism between the electric circuit and the mechanical properties

of the crystal, ensuring that the frequency of the mechanical acoustic wave is identically

equal to the electrical frequency, that is, a distortion-free interface having extremely

low dissipation.

2. The anisotropic nature of piezoelectric crystals allows for different angles of cut with

respect to the crystallographic axis, which, therefore, allows the use of crystals with a

range of frequencies.

Electrode

F2

Resistor

Figure 9.1 Transformation of mechanical energy into electrical energy

3

Note that this effect does not occur in crystalline silicon because its lattice structure is centro-symmetric.