Page 328 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 328

308 INTRODUCTION TO SAW DEVICES

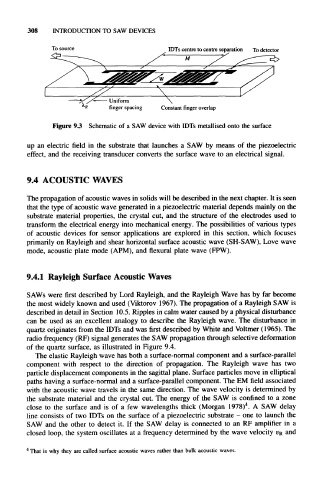

To source IDTs centre to centre separation To detector

— Uniform

finger spacing Constant finger overlap

Figure 9.3 Schematic of a SAW device with IDTs metallised onto the surface

up an electric field in the substrate that launches a SAW by means of the piezoelectric

effect, and the receiving transducer converts the surface wave to an electrical signal.

9.4 ACOUSTIC WAVES

The propagation of acoustic waves in solids will be described in the next chapter. It is seen

that the type of acoustic wave generated in a piezoelectric material depends mainly on the

substrate material properties, the crystal cut, and the structure of the electrodes used to

transform the electrical energy into mechanical energy. The possibilities of various types

of acoustic devices for sensor applications are explored in this section, which focuses

primarily on Rayleigh and shear horizontal surface acoustic wave (SH-SAW), Love wave

mode, acoustic plate mode (APM), and flexural plate wave (FPW).

9.4.1 Rayleigh Surface Acoustic Waves

SAWs were first described by Lord Rayleigh, and the Rayleigh Wave has by far become

the most widely known and used (Viktorov 1967). The propagation of a Rayleigh SAW is

described in detail in Section 10.5. Ripples in calm water caused by a physical disturbance

can be used as an excellent analogy to describe the Rayleigh wave. The disturbance in

quartz originates from the IDTs and was first described by White and Voltmer (1965). The

radio frequency (RF) signal generates the SAW propagation through selective deformation

of the quartz surface, as illustrated in Figure 9.4.

The elastic Rayleigh wave has both a surface-normal component and a surface-parallel

component with respect to the direction of propagation. The Rayleigh wave has two

particle displacement components in the sagittal plane. Surface particles move in elliptical

paths having a surface-normal and a surface-parallel component. The EM field associated

with the acoustic wave travels in the same direction. The wave velocity is determined by

the substrate material and the crystal cut. The energy of the SAW is confined to a zone

4

close to the surface and is of a few wavelengths thick (Morgan 1978) . A SAW delay

line consists of two IDTs on the surface of a piezoelectric substrate - one to launch the

SAW and the other to detect it. If the SAW delay is connected to an RF amplifier in a

closed loop, the system oscillates at a frequency determined by the wave velocity v R and

4

That is why they are called surface acoustic waves rather than bulk acoustic waves.