Page 374 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 374

354 IDT MICROSENSOR FABRICATION

12.3.2 TMS PECVD Process and Conditions

One of the necessary conditions for the deposition of SiO 2 is that the temperature of

deposition should be as low as possible. This is desirable because higher temperatures

can adversely affect the poling characteristics of quartz (in spite of the fact that quartz

is a naturally piezoelectric material) and because the melting point of the metallisation

layer (aluminum is 650 °C) should not be exceeded.

We should therefore choose SiO 2 that is either sputtered or deposited by plasma-

enhanced chemical vapour deposition (PECVD) from silane gas. The sputtering process

provides better step-coverage than evaporation and far less radiation damage than E-

beam evaporation (Campbell 1996). A simple sputtering system consists of a parallel-plate

plasma reactor in a vacuum chamber and the target material (SiO 2) placed on the electrode

such that it receives the maximum ion flux. An inert gas (at a pressure of 0.1 torr) is usually

used to supply the chamber with high-energy ions that strike the target at high velocities

and dislodge the SiO 2 molecules, which deposit conformal to the wafer (the SAW-IDT

device). The only disadvantage in this process is that on account of the physical nature

of the process, sputtering could also bombard and damage the delicate IDT fingers on the

surface of the quartz. Sputtering can also introduce a variety of contaminants from the

substrate holder because of the physical nature of the process. Hence, sputtering is not

the ideal means of depositing SiO 2, despite the fact that the process can be carried out

under conditions of low temperature.

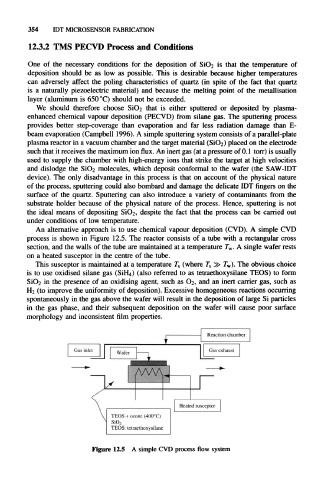

An alternative approach is to use chemical vapour deposition (CVD). A simple CVD

process is shown in Figure 12.5. The reactor consists of a tube with a rectangular cross

section, and the walls of the tube are maintained at a temperature T w. A single wafer rests

on a heated susceptor in the centre of the tube.

This susceptor is maintained at a temperature T s (where T s T w). The obvious choice

is to use oxidised silane gas (SiH 4) (also referred to as tetraethoxysilane TEOS) to form

in the presence of an oxidising agent, such as O2, and an inert carrier gas, such as

SiO 2

H2 (to improve the uniformity of deposition). Excessive homogeneous reactions occurring

spontaneously in the gas above the wafer will result in the deposition of large Si particles

in the gas phase, and their subsequent deposition on the wafer will cause poor surface

morphology and inconsistent film properties.

Figure 12.5 A simple CVD process flow system