Page 419 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 419

FABRICATION OF A MEMS-IDT ACCELEROMETER 399

the acceleration, the MEMS device can be used as an acceleration sensor. Alternatively,

the measurement can be done in the time domain, in which case the delay time of the

reflection from the reflectors is used to sense the acceleration.

14.3 FABRICATION OF A MEMS-IDT

ACCELEROMETER

We now illustrate the principles from the Worked Example 14.1 of a MEMS-IDT

accelerometer.

Worked Example E14.1: MEMS-IOT Accelerometer Objective:

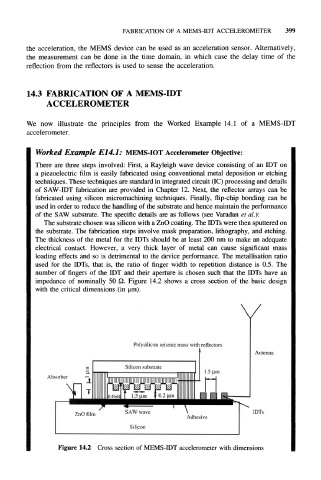

There are three steps involved: First, a Rayleigh wave device consisting of an IDT on

a piezoelectric film is easily fabricated using conventional metal deposition or etching

techniques. These techniques are standard in integrated circuit (1C) processing and details

of SAW-IDT fabrication are provided in Chapter 12. Next, the reflector arrays can be

fabricated using silicon micromachining techniques. Finally, flip-chip bonding can be

used in order to reduce the handling of the substrate and hence maintain the performance

of the SAW substrate. The specific details are as follows (see Varadan et al.):

The substrate chosen was silicon with a ZnO coating. The IDTs were then sputtered on

the substrate. The fabrication steps involve mask preparation, lithography, and etching.

The thickness of the metal for the IDTs should be at least 200 nm to make an adequate

electrical contact. However, a very thick layer of metal can cause significant mass

loading effects and so is detrimental to the device performance. The metallisation ratio

used for the IDTs, that is, the ratio of finger width to repetition distance is 0.5. The

number of fingers of the IDT and their aperture is chosen such that the IDTs have an

impedance of nominally 50 £2. Figure 14.2 shows a cross section of the basic design

with the critical dimensions (in um).

Polysihcon seismic mass with reflectors

Antenna

Absorber

IDTs

Figure 14,2 Cross section of MEMS-IDT accelerometer with dimensions