Page 44 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 44

26 ELECTRONIC MATERIALS AND PROCESSING

Etching-gas

inlet

Vacuum

enclosure

Electrodes

Pumping port

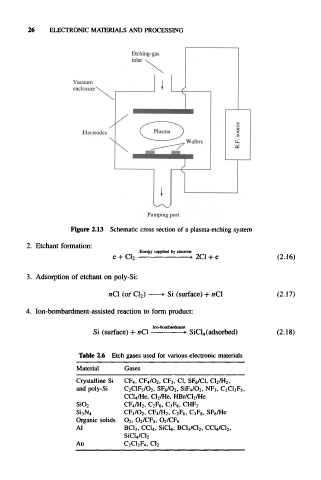

Figure 2.13 Schematic cross section of a plasma-etching system

2. Etchant formation:

Energy supplied by electron

> 2C1 + e (2.16)

e + C1 2

3. Adsorption of etchant on poly-Si:

nCl (or C1 2 ) » Si (surface) -I- nC\ (2.17)

4. lon-bombardment-assisted reaction to form product:

Ion-bombardment

Si (surface) + nCl > SiCl n(adsorbed) (2.18)

Table 2.6 Etch gases used for various electronic materials

Material Gases

Crystalline Si CF 4, CF 4/O 2, CF 3, Cl, SF 6 /C1, C1 2/H 2,

and poly-Si C 2C1F 5/O 2, SF 6/O 2, SiF 4/O 2, NF 3, C 2Cl 3F 5,

CCl 4/He, Cl 2/He, HBr/Cl 2/He

Si0 2 CF 4/H 2, C 2F 6, C 3F 8, CHF 3

CF 4/O 2, CF 4/H 2, C 2F 6, C 3F 8, SF 6/He

Si 3N 4

Organic solids O 2, O 2/CF 4, O 2/CF 6

Al BC1 3 , CCl 4, SiCl 4, BC1 3 /C1 2 , CCl 4/Cl 2,

SiCl 4/Cl 2

Au C 2C1 2F 4, C1 2