Page 42 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 42

24 ELECTRONIC MATERIALS AND PROCESSING

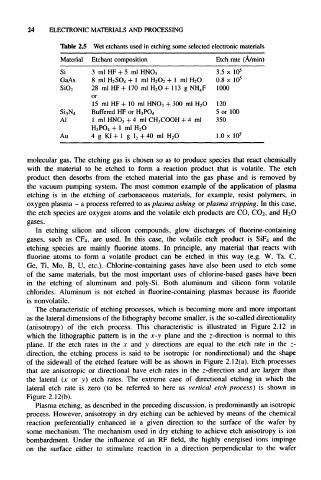

Table 2.5 Wet etchants used in etching some selected electronic materials

Material Etchant composition Etch rate (A/min)

Si 3 ml HF + 5 ml HNO 3 3.5 x 10 5

GaAs 8 ml H 2SO 4 + 1 ml H 2O 2 + 1 ml H 2O 0.8 x 10 5

28 ml HF + 170 ml H 2O + 113 g NH 4F 1000

SiO 2

or

15 ml HF -I- 10 ml HNO 3 + 300 ml H 2O 120

Buffered HF or 5 or 100

Si 3N 4 H 3PO 4

Al 1 ml HNO 3 + 4 ml CH 3COOH + 4 ml 350

+ 1 ml H 2O

H 3PO 4

Au 4 g KI + 1 g I 2 + 40 ml H 2O 1.0 x 10 5

molecular gas. The etching gas is chosen so as to produce species that react chemically

with the material to be etched to form a reaction product that is volatile. The etch

product then desorbs from the etched material into the gas phase and is removed by

the vacuum pumping system. The most common example of the application of plasma

etching is in the etching of carbonaceous materials, for example, resist polymers, in

oxygen plasma - a process referred to as plasma ashing or plasma stripping. In this case,

the etch species are oxygen atoms and the volatile etch products are CO, CO 2, and H2O

gases.

In etching silicon and silicon compounds, glow discharges of fluorine-containing

gases, such as CF4, are used. In this case, the volatile etch product is SiF 4 and the

etching species are mainly fluorine atoms. In principle, any material that reacts with

fluorine atoms to form a volatile product can be etched in this way (e.g. W, Ta, C,

Ge, Ti, Mo, B, U, etc.). Chlorine-containing gases have also been used to etch some

of the same materials, but the most important uses of chlorine-based gases have been

in the etching of aluminum and poly-Si. Both aluminum and silicon form volatile

chlorides. Aluminum is not etched in fluorine-containing plasmas because its fluoride

is nonvolatile.

The characteristic of etching processes, which is becoming more and more important

as the lateral dimensions of the lithography become smaller, is the so-called directionality

(anisotropy) of the etch process. This characteristic is illustrated in Figure 2.12 in

which the lithographic pattern is in the x-y plane and the z-direction is normal to this

plane. If the etch rates in the x and y directions are equal to the etch rate in the z-

direction, the etching process is said to be isotropic (or nondirectional) and the shape

of the sidewall of the etched feature will be as shown in Figure 2.12(a). Etch processes

that are anisotropic or directional have etch rates in the z-direction and are larger than

the lateral (x or y) etch rates. The extreme case of directional etching in which the

lateral etch rate is zero (to be referred to here as vertical etch process) is shown in

Figure 2. 12(b).

Plasma etching, as described in the preceding discussion, is predominantly an isotropic

process. However, anisotropy in dry etching can be achieved by means of the chemical

reaction preferentially enhanced in a given direction to the surface of the wafer by

some mechanism. The mechanism used in dry etching to achieve etch anisotropy is ion

bombardment. Under the influence of an RF field, the highly energised ions impinge

on the surface either to stimulate reaction in a direction perpendicular to the wafer