Page 43 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 43

ETCHING ELECTRONIC MATERIALS 25

(a) Isotropic etch (b) Vertical etch

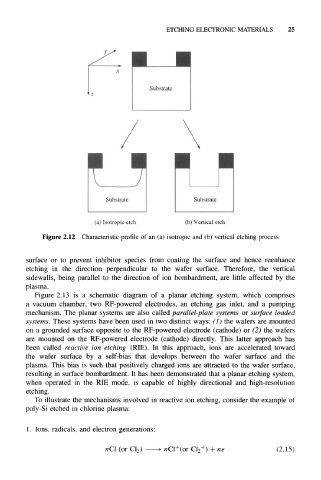

Figure 2.12 Characteristic profile of an (a) isotropic and (b) vertical etching process

surface or to prevent inhibitor species from coating the surface and hence reenhance

etching in the direction perpendicular to the wafer surface. Therefore, the vertical

sidewalls, being parallel to the direction of ion bombardment, are little affected by the

plasma.

Figure 2.13 is a schematic diagram of a planar etching system, which comprises

a vacuum chamber, two RF-powered electrodes, an etching gas inlet, and a pumping

mechanism. The planar systems are also called parallel-plate systems or surface loaded

systems. These systems have been used in two distinct ways: (1) the wafers are mounted

on a grounded surface opposite to the RF-powered electrode (cathode) or (2) the wafers

are mounted on the RF-powered electrode (cathode) directly. This latter approach has

been called reactive ion etching (RIE). In this approach, ions are accelerated toward

the wafer surface by a self-bias that develops between the wafer surface and the

plasma. This bias is such that positively charged ions are attracted to the wafer surface,

resulting in surface bombardment. It has been demonstrated that a planar etching system,

when operated in the RIE mode, is capable of highly directional and high-resolution

etching.

To illustrate the mechanisms involved in reactive ion etching, consider the example of

poly-Si etched in chlorine plasma:

1. Ions, radicals, and electron generations:

+

+

(or C1 2) > nCl (or C1 2 ) + ne (2.15)