Page 40 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 40

22 ELECTRONIC MATERIALS AND PROCESSING

Radiation

Mask

Resist

Substrate

(b)

Deposit

Substrate Substrate

(c) (d)

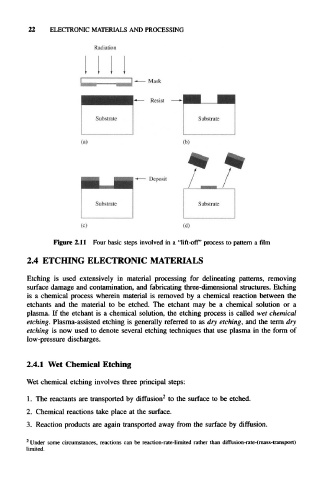

Figure 2.11 Four basic steps involved in a "lift-off' process to pattern a film

2.4 ETCHING ELECTRONIC MATERIALS

Etching is used extensively in material processing for delineating patterns, removing

surface damage and contamination, and fabricating three-dimensional structures. Etching

is a chemical process wherein material is removed by a chemical reaction between the

etchants and the material to be etched. The etchant may be a chemical solution or a

plasma. If the etchant is a chemical solution, the etching process is called wet chemical

etching. Plasma-assisted etching is generally referred to as dry etching, and the term dry

etching is now used to denote several etching techniques that use plasma in the form of

low-pressure discharges.

2.4.1 Wet Chemical Etching

Wet chemical etching involves three principal steps:

1. The reactants are transported by diffusion 2 to the surface to be etched.

2. Chemical reactions take place at the surface.

3. Reaction products are again transported away from the surface by diffusion.

2

Under some circumstances, reactions can be reaction-rate-limited rather than diffusion-rate-(mass-transport)

limited.