Page 186 - Modular design for machine tools

P. 186

146 Modular Design Guide and Machine Tools Description

(a)

Z

Z

A

A

3,600

WP CS WP CS

Y C'

C' Y

X'

X

4,100

4,100

Nr102 Y Z A CS WP C' X'

(b)

Z

A

3,700 WP CS

X

C'

Y

4,100

3,600

Nr116 Y X Z A CS WP C'

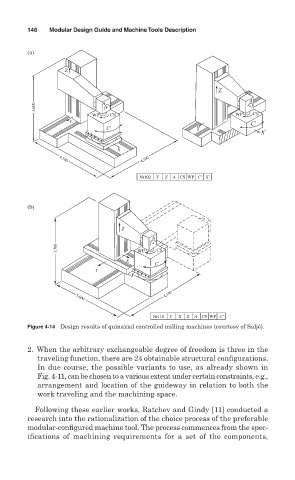

Figure 4-14 Design results of quinaxial controlled milling machines (courtesy of Saljé).

2. When the arbitrary exchangeable degree of freedom is three in the

traveling function, there are 24 obtainable structural configurations.

In due course, the possible variants to use, as already shown in

Fig. 4-11, can be chosen to a various extent under certain constraints, e.g.,

arrangement and location of the guideway in relation to both the

work traveling and the machining space.

Following these earlier works, Ratchev and Gindy [11] conducted a

research into the rationalization of the choice process of the preferable

modular- configured machine tool. The process commences from the spec-

ifications of machining requirements for a set of the components,