Page 181 - Modular design for machine tools

P. 181

Application of Machine Tool Description to Engineering Design 141

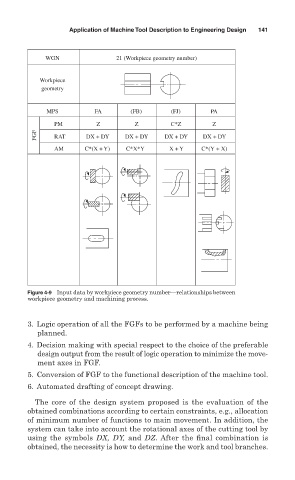

WGN 21 (Workpiece geometry number)

Workpiece

geometry

MPS FA (FB) (FJ) PA

PM Z Z C*Z Z

FGF RAT DX + DY DX + DY DX + DY DX + DY

AM C*(X + Y) C*X*Y X + Y C*(Y + X)

Figure 4-9 Input data by workpiece geometry number—relationships between

workpiece geometry and machining process.

3. Logic operation of all the FGFs to be performed by a machine being

planned.

4. Decision making with special respect to the choice of the preferable

design output from the result of logic operation to minimize the move-

ment axes in FGF.

5. Conversion of FGF to the functional description of the machine tool.

6. Automated drafting of concept drawing.

The core of the design system proposed is the evaluation of the

obtained combinations according to certain constraints, e.g., allocation

of minimum number of functions to main movement. In addition, the

system can take into account the rotational axes of the cutting tool by

using the symbols DX, DY, and DZ. After the final combination is

obtained, the necessity is how to determine the work and tool branches.