Page 264 - Modular design for machine tools

P. 264

Engineering Design Fundamentals and Single Flat Joint Characteristics 223

uncertainty in quantitatively determining the magnitude of the flatness

deviation, although the surface roughness can clearly be indicated on the

drawing. This induces another problem—the test specimen with quan-

tified flatness deviation cannot be produced. In consideration of such

unfavorable influences of the flatness deviation on the joint stiffness, they

reported the value b* for the single flat joint under higher normal load-

ing and not showing any local deformation, such as shown in Table 6-6.

Importantly, a further problem in the expression of the joint stiffness

under higher interface pressure is to establish a modified expression

with special respect to the bolted joint, which is preferably based on that

of Ostrovskii and takes into consideration an effect of cross receptance,

i.e., mutual spring action of nonlinear type [12]. With the increase of the

interface pressure, the cross receptance in the joint stiffness could become

generally strong; however, the details have not yet been clarified.

To this end, the wider applicability of the expression of Ostrovskii will

be stated. In accordance with the expression of Levina, the value of m for

the slideway under lower interface pressure can be regarded as unit, and

thus the joint stiffness per unit area is equal to C as already shown in

for such a

Table 6-1. In due course, Levina suggested the value of C 0

slideway shown in Table 6-7, and verified its validity in the engineering

calculation. Figure 6-3 is two examples of the comparison between the the-

oretical and experimental values, and as can be seen, good agreement

between both values can be observed. In the slideway, furthermore, at

issue is the flat joint subjected to complex loading, i.e., normal loading with

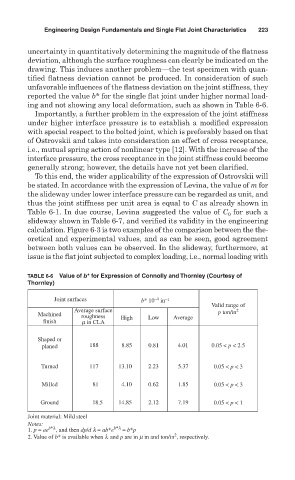

TABLE 6-6 Value of b* for Expression of Connolly and Thornley (Courtesy of

Thornley)

Joint surfaces b* 10 in –1

–4

Valid range of

Average surface p ton/in 2

Machined roughness High Low Average

finish m in CLA

Shaped or

planed 188 8.85 0.81 4.01 0.05 < p < 2.5

Turned 117 13.10 2.23 5.37 0.05 < p < 3

Milled 81 4.10 0.62 1.85 0.05 < p < 3

Ground 18.5 14.85 2.12 7.19 0.05 < p < 1

Joint material: Mild steel

Notes:

1. p = ae b*l , and then dp/d l = ab*e b*l = b*p

2

2. Value of b* is available when l and p are in m in and ton/in , respectively.