Page 269 - Modular design for machine tools

P. 269

228 Engineering Design for Machine Tool Joints

7

1

6

5

Joint deflection l, mm 4 2

3

4

3

2 5

6

7

1

0 12 5 10 16 25

Interface pressure p, kgf/cm 2

2

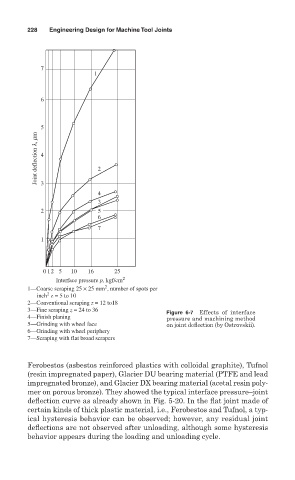

1—Coarse scraping 25 × 25 mm , number of spots per

2

inch z = 5 to 10

2—Conventional scraping z = 12 to18

3—Fine scraping z = 24 to 36

Figure 6-7 Effects of interface

4—Finish planing pressure and machining method

5—Grinding with wheel face on joint deflection (by Ostrovskii).

6—Grinding with wheel periphery

7—Scraping with flat broad scrapers

Ferobestos (asbestos reinforced plastics with colloidal graphite), Tufnol

(resin impregnated paper), Glacier DU bearing material (PTFE and lead

impregnated bronze), and Glacier DX bearing material (acetal resin poly-

mer on porous bronze). They showed the typical interface pressure–joint

deflection curve as already shown in Fig. 5-20. In the flat joint made of

certain kinds of thick plastic material, i.e., Ferobestos and Tufnol, a typ-

ical hysteresis behavior can be observed; however, any residual joint

deflections are not observed after unloading, although some hysteresis

behavior appears during the loading and unloading cycle.