Page 178 - Book Hosokawa Nanoparticle Technology Handbook

P. 178

FUNDAMENTALS CH. 3 CHARACTERISTICS AND BEHAVIOR OF NANOPARTICLES AND ITS DISPERSION SYSTEMS

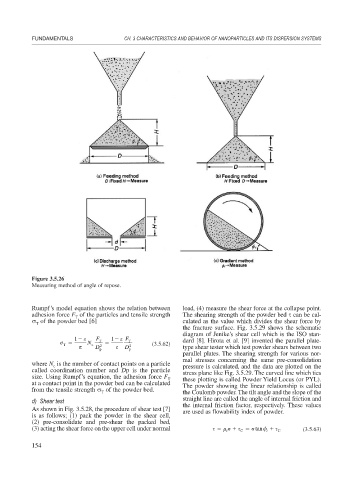

Figure 3.5.26

Measuring method of angle of repose.

Rumpf’s model equation shows the relation between load, (4) measure the shear force at the collapse point.

adhesion force F of the particles and tensile strength The shearing strength of the powder bed can be cal-

T

of the powder bed [6] culated as the value which divides the shear force by

T

the fracture surface. Fig. 3.5.29 shows the schematic

diagram of Jenike’s shear cell which is the ISO stan-

1 F 1 F

N c T T (3.5.62) dard [8]. Hirota et al. [9] invented the parallel plate-

T

D p 2 D p 2 type shear tester which test powder shears between two

parallel plates. The shearing strength for various nor-

mal stresses concerning the same pre-consolidation

where N is the number of contact points on a particle pressure is calculated, and the data are plotted on the

c

called coordination number and Dp is the particle stress plane like Fig. 3.5.29. The curved line which ties

size. Using Rumpf’s equation, the adhesion force F T these plotting is called Powder Yield Locus (or PYL).

at a contact point in the powder bed can be calculated The powder showing the linear relationship is called

from the tensile strength of the powder bed. the Coulomb powder. The tilt angle and the slope of the

T

straight line are called the angle of internal friction and

d) Shear test

the internal friction factor, respectively. These values

As shown in Fig. 3.5.28, the procedure of shear test [7] are used as flowability index of powder.

is as follows; (1) pack the powder in the shear cell,

(2) pre-consolidate and pre-shear the packed bed,

(3) acting the shear force on the upper cell under normal tan i C (3.5.63)

C

i

154