Page 251 - Book Hosokawa Nanoparticle Technology Handbook

P. 251

4.5 STRUCTURE CONTROL OF NANOPARTICLE COLLECTIVES BY SINTERING AND BONDING

Murata Manufacturing

Toshiba Corp.

Co., Ltd.

8.5

6.1

8.0

5.4

5.4

8.0

Bending Manufacturer Dielectric Thermal Thermal constant conductivity expansion strength at 1 MHz (W/m°C) coefficient (MPa) (ppm/°C) Asahi Glass Co., Ltd. 7.4 4.2 5.9 235 7.9 2.5 6.3 204 Kyocera Corp. 5.0 2 4.0 190 6.2 3 4.2 210 Dupont 8.0 —- 7.9 200 NEC Corp. 7.8 4.2 4.2 300 4.7 3.5 3.5 140 3.4 —- 3.2 85 Noritake Co., Ltd. 7.4 8.4 7.6 140 Hitachi, Ltd. 7.0 1.7 5.5 200 Fujitsu Limited 4.9 4 4.0 200 Matsushita Electric 7.4 3 6.0 260 Industrial Co., Ltd. Murata Manufacturing 7.7 2.5 5.5 200 C

200

200

Conductor a (3) (4) (2) (2) (1) (1)(3)(4) (3) (2) (1) (2)(3) (1)(3) (2) (2) (1)(2)(3) (2) (2) (4) (2) (3)(4) (2)

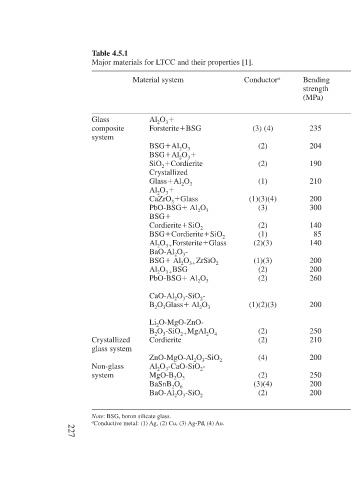

Major materials for LTCC and their properties [1].

Material system Al 2 O 3 Forsterite BSG BSG Al 2 O 3 BSG Al 2 O 3 SiO 2 Cordierite Crystallized Glass Al 2 O 3 Al 2 O 3 CaZrO 3 Glass Al 2 O 3 PbO-BSG BSG Cordierite SiO 2 BSG Cordierite SiO 2 Al 2 O 3 Forsterite Glass BaO-Al 2O 3 - Al 2 O 3 ZrSiO 2 BSG Al 2 O 3 BSG Al 2 O 3 PbO-BSG CaO-Al 2O 3 -SiO 2- Al 2 O 3 B 2 O 3Glass Li 2O-MgO-ZnO- B 2 O 3-SiO 2 MgAl 2O 4 Cordierite ZnO-MgO-Al 2O 3 -SiO 2 Al 2 O 3 -CaO-SiO 2- MgO-B 2 O 3 BaSnB 2O 6 BaO-Al 2O 3 -SiO 2 a Conductive metal: (1) Ag, (2) Cu, (3) Ag-Pd, (4) Au.

Table 4.5.1 Glass composite system Crystallized glass system Non-glass system Note: BSG, boron silicate glass.

227