Page 87 - Offshore Electrical Engineering Manual

P. 87

74 CHAPTER 5 Generation and Distribution Switchgear and Transformers

(A)

(B) Bellows A

End caps Envelope Contact tip Cup End caps

Moving contact

Fixed contact

A A

A

V2O4

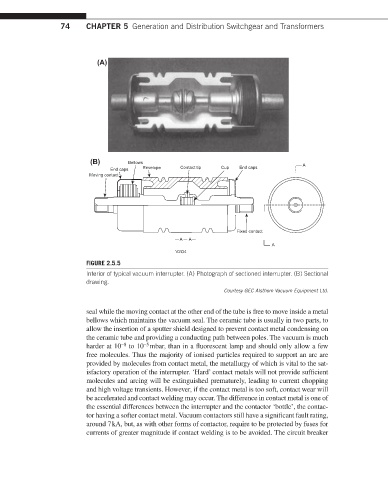

FIGURE 2.5.5

Interior of typical vacuum interrupter. (A) Photograph of sectioned interrupter. (B) Sectional

drawing.

Courtesy GEC Alsthom Vacuum Equipment Ltd.

seal while the moving contact at the other end of the tube is free to move inside a metal

bellows which maintains the vacuum seal. The ceramic tube is usually in two parts, to

allow the insertion of a sputter shield designed to prevent contact metal condensing on

the ceramic tube and providing a conducting path between poles. The vacuum is much

harder at 10 to 10 mbar, than in a fluorescent lamp and should only allow a few

−5

−8

free molecules. Thus the majority of ionised particles required to support an arc are

provided by molecules from contact metal, the metallurgy of which is vital to the sat-

isfactory operation of the interrupter. ‘Hard’ contact metals will not provide sufficient

molecules and arcing will be extinguished prematurely, leading to current chopping

and high voltage transients. However, if the contact metal is too soft, contact wear will

be accelerated and contact welding may occur. The difference in contact metal is one of

the essential differences between the interrupter and the contactor ‘bottle’, the contac-

tor having a softer contact metal. Vacuum contactors still have a significant fault rating,

around 7 kA, but, as with other forms of contactor, require to be protected by fuses for

currents of greater magnitude if contact welding is to be avoided. The circuit breaker