Page 133 - Optical Communications Essentials

P. 133

Connectors and Splices

Connectors and Splices 123

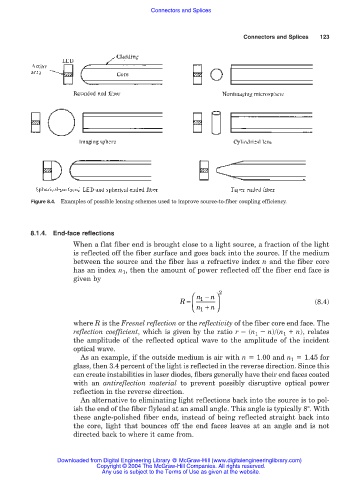

Figure 8.4. Examples of possible lensing schemes used to improve source-to-fiber coupling efficiency.

8.1.4. End-face reflections

When a flat fiber end is brought close to a light source, a fraction of the light

is reflected off the fiber surface and goes back into the source. If the medium

between the source and the fiber has a refractive index n and the fiber core

has an index n 1 , then the amount of power reflected off the fiber end face is

given by

n − 2

n

R = 1 (8.4)

n +

1 n

where R is the Fresnel reflection or the reflectivity of the fiber core end face. The

reflection coefficient, which is given by the ratio r (n 1 n)/(n 1 n), relates

the amplitude of the reflected optical wave to the amplitude of the incident

optical wave.

As an example, if the outside medium is air with n 1.00 and n 1 1.45 for

glass, then 3.4 percent of the light is reflected in the reverse direction. Since this

can create instabilities in laser diodes, fibers generally have their end faces coated

with an antireflection material to prevent possibly disruptive optical power

reflection in the reverse direction.

An alternative to eliminating light reflections back into the source is to pol-

ish the end of the fiber flylead at an small angle. This angle is typically 8°. With

these angle-polished fiber ends, instead of being reflected straight back into

the core, light that bounces off the end faces leaves at an angle and is not

directed back to where it came from.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.