Page 172 - Optofluidics Fundamentals, Devices, and Applications

P. 172

Optofluidic Photonic Crystal Fibers: Pr operties and Applications 147

Integrated Long-period

(b)

heaters grating

Splice V pump V grat Splice

(c)

V pump V grat High-index fluid

Core Cladding Low-index fluid

mode mode

0 0

Transmission (dB) –4 T grat 1558 20 T grat (°C) 80 110 Transmission (dB) –4 T pump Γ LPG 0.8 150 Temp (°C)

1.0

50

–8

–8

100

0.6

71°C

54°C

0.2

98°C

1550

–12 25°C λres (nm) 1554 –12 25°C 0.4 50

0

83°C

L grat (cm)

116°C 1546 126°C 0 12 3 4

1530 1540 1550 1560 1570 1580 1530 1540 1550 1560 1570

(a) (b)

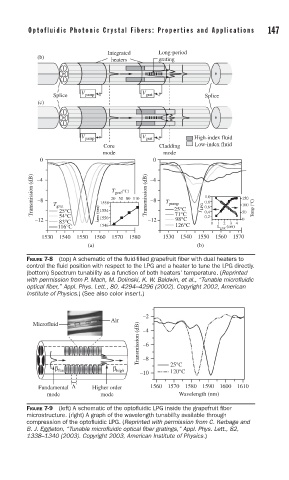

FIGURE 7-8 (top) A schematic of the fl uid-fi lled grapefruit fi ber with dual heaters to

control the fl uid position with respect to the LPG and a heater to tune the LPG directly.

(bottom) Spectrum tunability as a function of both heaters’ temperature. (Reprinted

with permission from P. Mach, M. Dolinski, K. W. Baldwin, et al., “Tunable microfl uidic

optical fi ber,” Appl. Phys. Lett., 80, 4294–4296 (2002). Copyright 2002, American

Institute of Physics.) (See also color insert.)

–2

Air

Transmission (dB) –6

Microfluid –4

β –8 25°C

β fun high 120°C

–10

Fundamental Λ Higher order 1560 1570 1580 1590 1600 1610

mode mode Wavelength (nm)

FIGURE 7-9 (left) A schematic of the optofl uidic LPG inside the grapefruit fi ber

microstructure. (right) A graph of the wavelength tunability available through

compression of the optofl uidic LPG. (Reprinted with permission from C. Kerbage and

B. J. Eggleton, “Tunable microfl uidic optical fi ber gratings,” Appl. Phys. Lett., 82,

1338–1340 (2003). Copyright 2003, American Institute of Physics.)